How is laminated glass manufactured?

Fangding Technology Co.,Ltd.

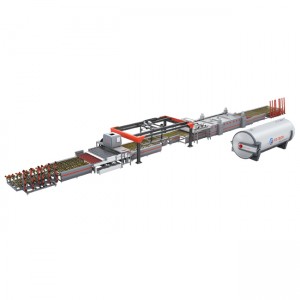

FOUR-LAYER,DOUBLE CIRCULATION

EVALAMINATED GLASS MACHINE

Newly Upgraded Safe and Reassuring

Product Introduction

Fangding Latest 2-Layer glass lamination furnace

The glass laminating furnace adopts the principle of high temperature vacuum extraction. The film is placed in the middle of two or more pieces of glass. After the high temperature vacuum in the furnace, the film and glass are tightly bonded together to achieve good transparency and no bubbles. And there is no drop after breaking.

* Independent heating up and down, floor heating distribution, modular control, strong convection circulation of turbine

* A number of patented technologies.The heating system uses a turbine fan and a high-density explosion-proof stainless steel electric heating rod for heating. It is equipped with a temperature sensing device, a modular area heating control, intelligent self-adjusting temperature, fast heating, uniform temperature, and strong turbo fan. Convection circulation to ensure the temperature difference in the furnace within 5 degrees.

* The insulation system adopts seamless processing to minimize heat loss. Compared with similar products and equipment, it can save energy by more than 30%.

* High-performance vacuum system with automatic vacuum pressure holding, stable working around the clock, improving product efficiency and quality.

| Model | Glass size | Control system | Floor space(MM) | Weight(KG) | Power(KW) | Process time(Min) | Production capacity(m²) | Dimenision(MM) |

| FD-J-2-4 | 2000*3000*4 | Siemens PLC | 3720*9000 | 3700 | 55 | 40 ~ 120 | 72 | 2530*4000*2150 |

| FD-J-3-4 | 2200*3200*4 | Siemens PLC | 4020*9500 | 3900 | 65 | 40 ~ 120 | 84 | 2730*4200*2150 |

| FD-J-4-4 | 2200*3600*4 | Siemens PLC | 4020*10500 | 4100 | 65 | 40 ~ 120 | 96 | 2730*4600*2150 |

| FD-J-5-4 | 2440*3660*4 | Siements PLC | 4520*10500 | 4300 | 70 | 40 ~ 120 | 107 | 2965*4600*2150 |

Features

* 99% pass rate

* 50% energy saving

* High efficiency

* PLC control, Simple to operate

* High quality spare parts

* EVA/TPU/SGP film as interlayer

* Rich range of products

* Large size bending glass processing

* No waste when suddenly power off

* Free home installation and training

Specification:

| Model | Processing glass size (mm) | Rated power | N.W. | Outside dimonsion (mm) | Floor space (mm) | Production capacity (m2/cycle) |

| FD-J-2-2 | 2000*3000*2 layers | 26kw | 2200kgs | 2600*4000*1150 | 3700*9000 | 36 |

| FD-J-3-2 | 2200*3200*2 layers | 28kw | 2400kgs | 2750*4200*1150 | 4000*9500 | 42 |

| FD-J-4-2 | 2200*3660*2layers | 30kw | 2500kgs | 2750*4600*1150 | 4000*10500 | 48 |

| FD-J-5-2 | 2440*3660*2layers | 33kw | 2600kgs | 2980*4600*1150 | 4500*10500 | 5 |

| Place of Origin | Shandong, China |

| Voltage | 220/380/440V, can be customized |

| Certification | CE, CSA,UL |

| Warranty | 1 Year |

| After-sale service | Online support, Free spare parts, Field installation, commissioning and training, Video technical support |

| Glass Thickness | 3-19mm |

| Core Components | Motor, heating tube, PLC, Pump |

| Product name | EVA Glass Laminating Machine |

| Operating temperature | 90-140℃ |

| Control system | PLC |

| PLC | Siemens Brand |

| Heating method | Forced Convection |

| Operation | Automatic Control |

| Processable glass type | Normal Glass |

Scientific Design

Selling point description

FEATURES

1. The machine have 2 operation systems, can laminate different kinds of glass with different parameters at the same time, realize cycle work, reduce costs and and increase efficiency.

2. The independent vacuum system has the functions of power failure and pressure maintenance, oil-water separation, pressure relief alarm, maintenance reminder, dust prevention and noise reduction, etc.

3. Multi-layer independent heating and modular area heating control, make the machine has fast heating speed, high efficiency and small temperature difference.

4. The insulation layer is seamlessly processed to reduce heat loss, the insulation effect is stronger, and it is more energy-saving.

5. The machine adopts PLC control system and the new humanized UI interface, the whole process of machine status can be visualized, and all procedures can be completed automatically.

6. New upgraded design, the lifting platform has a one-button lifting function, and the full-load glass lifts without deformation and rebound.

Company

Packing & Delivery

Wrapped with moisture proof film

Plywood suitable for container loading

CUSTOMER CASE

The equipment is sold to Asia, Europe, Ameriaca, Southeast Asia, and has received unanimous praise from customers;

Good customer performance and the ability to mass produce orders;

Morecustomers choose to order a second unit and repeat orders for high-pressure reactors, production lines, and other products.

CUSTOMER USE CASES

The products produced by customers using equipment can be seen everywhere in daily life, such as wire clips, colored decorative glass, etc; And it has also been used in important engineering cases of world-renowned buildings and scenic spots such as glass bridges and lighthouses.

CERTIFICATE OF HONOR

R&D TECHNOLOGY TEAM

Hold a technical

review meeting

before production

Calculation based

on drawings

before production

Multiple

experienced

technical engineers

EXHIBITION STYLE

The company participated in the world glass industry well-known exhibitions every year, such as Germany Dusseldorf international glass industry exhibition, China international glass industry exhibition, China international window and curtain wall exhibition, Italy Milan international glass industry exhibition, the Middle East (Dubai) international glass exhibition, the United States Atlanta international window and curtain wall exhibition and other exhibitions.

During the exhibition, through the on-site processing of the laminated glass, Fangding presented its unique design style and manufacturing process to the customers!

Application

Outdoor architecture glass and indoor decorative glass, including glass wall, ordinary float laminated glass, curved laminated glass, tempered laminated glass, high-level office building, furniture, church, villa, wall windowpane, tabletop, craft glass, colored laminated glass, LED glass, smart glass, bullet-proof glass, multi-layer laminated glass, laminated silk glass, household appliances panel glass, glass corner, background wall and video wall glass, coffee table surface glass, partition screen, frameless painting laminated glass and personalized portrait glass etc.

FAQ

Q: Could your machines laminate bent tempered glass?

A: Yes. Our machines can laminate large-size bent tempered glass in one step, which is very easy to operate.

Q: How many stages your machines can set?

A: Normally we set 3 stages. It can be customized for you to 5 stages if needed.

Q: When will your machine ready for delivery after our prepayment?

A: Normally within in 30 days after receiving prepayment.

Q: What about the terms of payment?

A: Normally 30% prepayment, 70% before shipment by T/T. L/C and other terms are also available.

Q: Does your machine have any certifications?

A: Yes, we do. Our machine have got CE certificate of European union, ISO9001 management system certificate. TUV certificate of Germany, PC certificate for Saudi Arabia, CSA certificate of Canada and so on.

Q: Could the laminated glass used for exterior?

A: Yes. The laminated glass with super clear EVA can be totally used for exterior.

Q: How to operate the machine? Is it difficult?

A: No, our machine is very easy to operate. The machine will work automatically after you setting the parameters through the PLC touch screen. We send you operating manual with the machine, we also have video for operation for your reference.

CONTACT US

Jennifer Zhu

HOT LINE +86-18906338322

Website: https://en.fangdingchina.com/

Email: sales2@foundite.com

Add: Huifeng Road, Taoluo Industrial Park, Donddang District, Rizhao City, Shandong Province, China