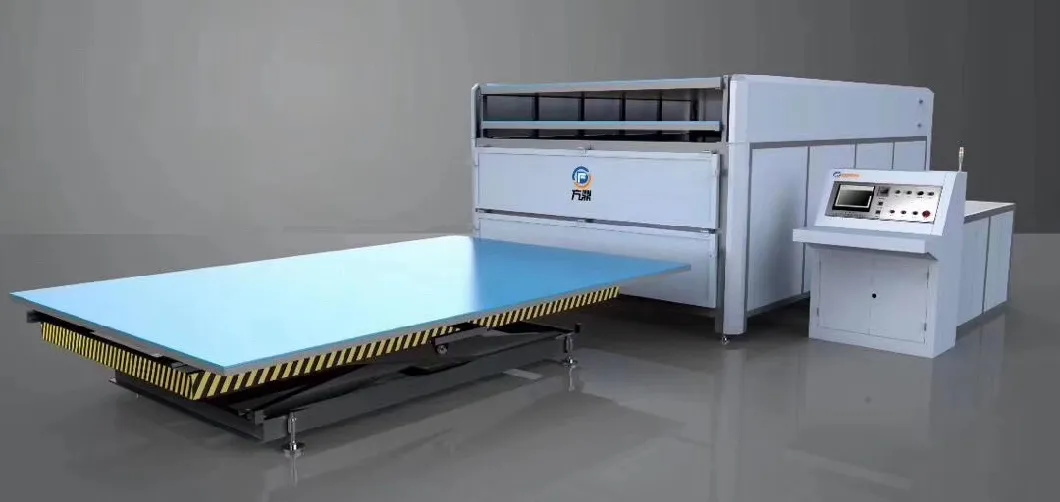

OEM/ODM Factory Glass Vacuum Laminated Device - Fangding 2021 Newest Design Vacuum and Heat EVA Processing Glass Laminating Machine – Fangding

OEM/ODM Factory Glass Vacuum Laminated Device - Fangding 2021 Newest Design Vacuum and Heat EVA Processing Glass Laminating Machine – Fangding Detail:

PRODUCT NAME: Fangding EVA glass laminating machine

ITEM#: FD-J-5-4

MAIN TECHNICAL PARAMETERS:

POWER INPUT: 220-440V THREEPHASE ALTERBATING CURRENT

POWER CONSUMPTION: 58KW / H

MAX PROCESSING GLASS SIZE: Max size (mm): 2440 mm*3660mm

Max Arch height (mm): 400 mm(can design as your requirement even higher)

Max Thickness (mm): 36 mm

EFFICIENCY: Forming cycle (minute/furnace): 75-90min

Max processing area (M2 /furnace): 107M2

OPERATION SYSTEM: PLC, Man machine conversation.

OPERATION PLATEFORM: 4 layers

WORKING TEMPERATURE: 90-140 0C

MACHINERY OUTSIDE DIMENTION :2965mm*4600mm*2150mm

N.W: 4300kgs

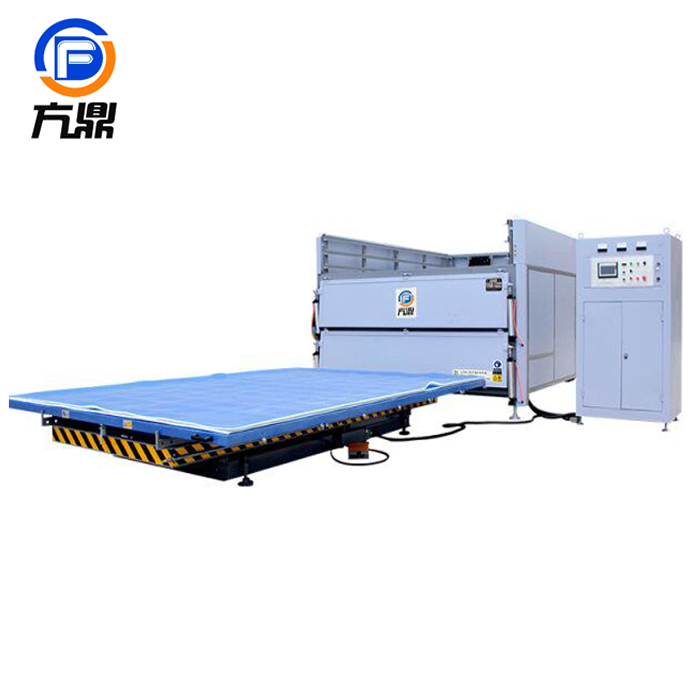

It has 4 work platforms, with 2 PLC control system, 2 heating system, 2 vacuum system.

equipped with automatic lifting platform.

The heating room has been separated to two independent chambers by one flat cross wall—

upper and bottom chamber. Each chamber has its own control system, Therefore the two

chambers could independent work at the same time.

1. High efficiency and more flexible. Single workstation and double workstation could be changed easily.

If you get more laminated glass orders, two chambers can save the preparation time and it use the

afterheat to process next cycle, save energy.

If small order, you can use only one chamber, another one off work. This will save consumption of the

electricity.

2. You can use the two chambers for different kinds of lamination. Different parameters can be pre-set

on the two PLC systems. This will meet different order requirements very well. For example, you can

process tempered laminated glass in the upper room, and process PDLC laminated glass in the bottom

room. Almost like that you own two small machines.

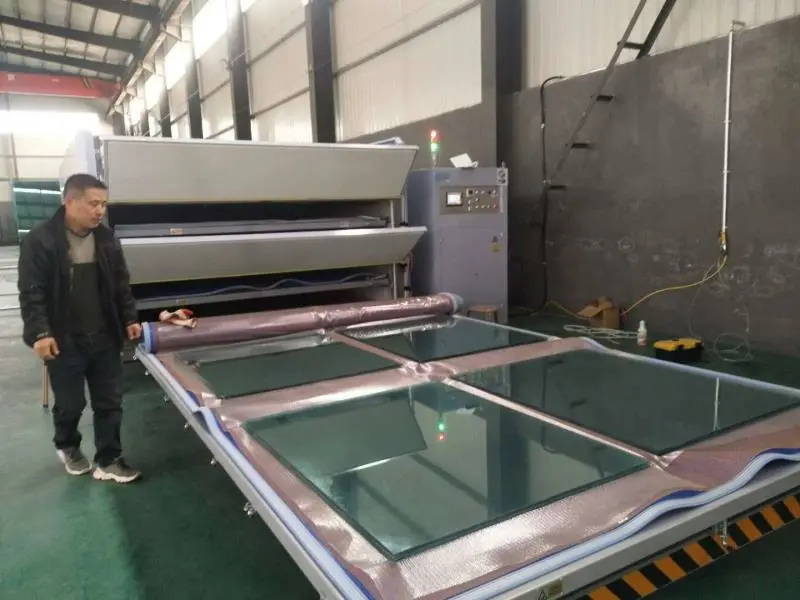

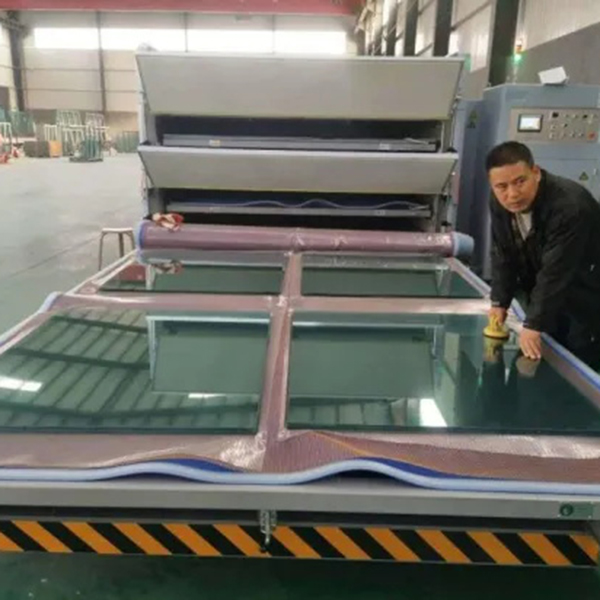

Bending temper glass laminating processing in the fair.

FANGDING GLASS LAMINATING IN CUSTOMERS FACTORY:

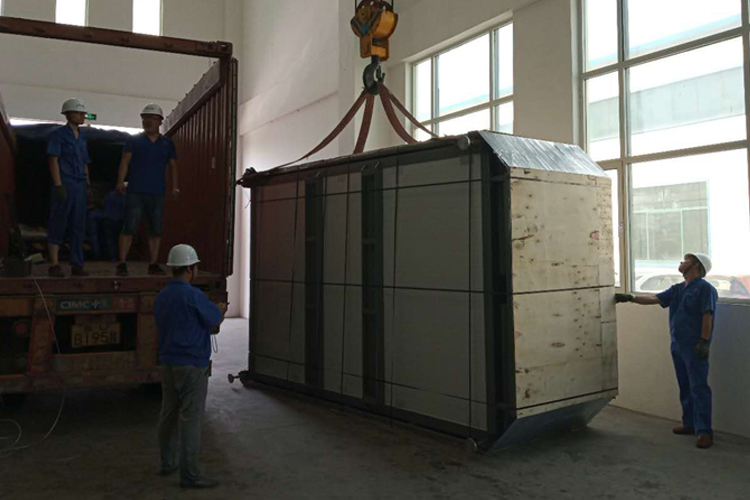

AFTER SALE SERVICE:

Installation and technical training:

If the buyer needs the seller to install the machine and offering the technical training to the factory. The buyer need pay for

the sellers air ticket, hotel, food and so on the basic cost.traing service is free.

QUALITY WARRANTY:12 months.(during the time ,if any broken any spare parts, we will send for free, only

the shipping cost is one customers charge)

Shipping to Canada

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for OEM/ODM Factory Glass Vacuum Laminated Device - Fangding 2021 Newest Design Vacuum and Heat EVA Processing Glass Laminating Machine – Fangding, The product will supply to all over the world, such as: Albania, Turkmenistan, Belarus, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We are looking forward to cooperating with friends from all over the world.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!