Autoclave laminated glass equipment is one of the important equipment used for the production of laminated glass in the glass processing industry. Laminated glass is a composite material composed of one or more layers of plastic film (such as PVB, EVA or SGP, etc.) sandwiched between two or more layers of glass, and the film is closely combined with the glass through the high temperature and high pressure treatment of the autoclave to form a glass product with certain strength and safety. With its efficient and stable production capacity and high-quality products, autoclave laminated glass equipment has been widely used in construction, automobile, transportation, home appliances and other fields.

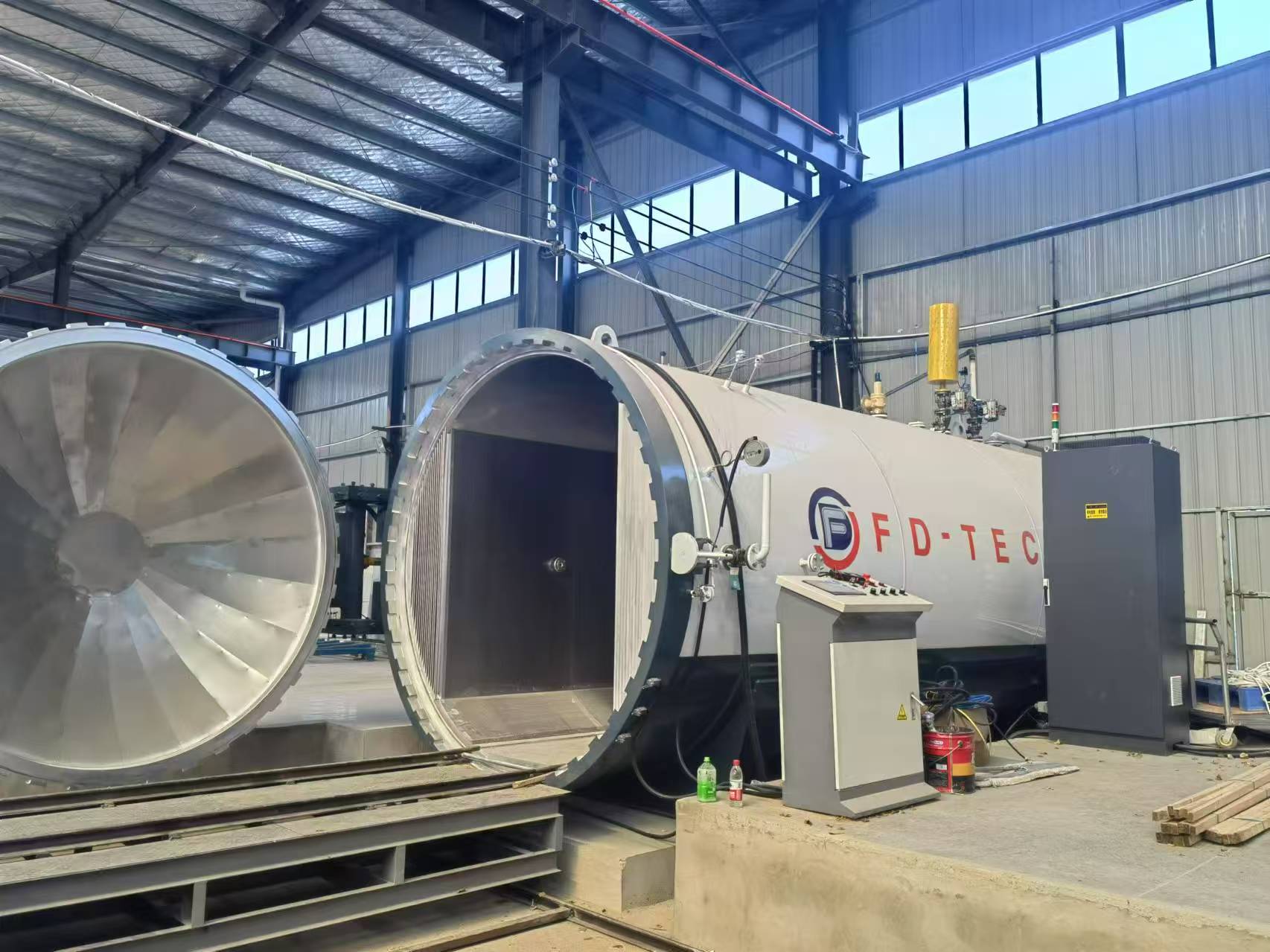

The autoclave laminated glass equipment is mainly composed of tank, heating system, cooling system, insulation system, control system and other parts.

tanks

The tank body of the autoclave is the main pressure-bearing part of the equipment, which is generally processed by the special steel plate Q345R for pressure vessels. This material has a better pressure bearing effect than ordinary steel plates, and the tank body is automatically welded, and there is no porosity, trachoma, and unwelded penetration in the weld, which ensures the overall strength and tightness of the equipment.

Heating system

The heating system usually adopts a wrap-around electric heating tube, and the heating method adopts electric heating, and the heating speed is adjustable. The heating tube is made of stainless steel and has a long service life. The heating system makes the temperature in the tank meet the process requirements by setting the heating temperature and heating time, so as to realize the heating treatment of glass and film.

Cooling system

The cooling system is equipped with a vacuum cooling device for cooling in the tank after the work is completed. When the heat treatment is completed, the temperature in the tank is rapidly reduced through the cooling system, so that the glass and film are quickly cooled and solidified, and the quality and performance of the product are guaranteed.

Thermal insulation system

The insulation system has a built-in double-layer aluminum silicate insulation cotton, which has a good insulation effect. The insulation system can reduce the heat loss in the tank, improve the heating efficiency, and ensure the uniform distribution of temperature in the tank, and improve the product quality.

Control system

The control system is the core part of the autoclave laminated glass equipment, including power switch, heating temperature setting, preheating temperature setting, exhaust temperature setting, holding time setting, exhaust valve control, swing closing control, rotary closing door control, handle switch control, etc. The control system realizes accurate control and stable operation of the equipment by setting and monitoring various parameters.

The working principle of autoclave laminated glass equipment is as follows:

The manipulator pushes the glass-clamped cart into the kettle and closes the kettle door.

Set parameters such as heating temperature, preheating temperature, exhaust temperature, and holding time, and start the autoclave.

The heating system starts to heat, and when the temperature reaches the set value, the heating stops and the glue is evenly sprayed on the glass surface through the nozzle in the kettle controlled by the program.

After holding the autoclave for a period of time, turn on the cooling water pump to reduce the temperature in the kettle to the set value and stop the autoclave.

The exhaust valve automatically opens and exhausts, when the air pressure in the kettle is exhausted, the no pressure in the operating cabinet is displayed, the handle switch is opened, the door is opened, the door is rotated, and the glass is taken out.

The laminated glass autoclave produced by Fangding can make flat and curved laminated glass, can realize automatic control of temperature and pressure programs, and is equipped with a safety interlock device, so that the equipment can not only ensure the yield of product quality but also ensure safety during operation. Equipment accessories use Siemens, Delixi and other well-known brands to ensure the stability of equipment parts.

|

LAMINATED GLASS AUTOCLAVE |

|||

|

Name |

Units |

DN2860*6000 |

DN3000*6000 |

|

Inner diameter |

mm |

2860 |

3000 |

|

Glass length |

mm |

6000 |

6000 |

|

Max.glass size |

mm |

2440*6000 |

2600*6000 |

|

Max.press |

Mpa |

1.5 |

1.5 |

|

Max.temp |

℃ |

160 |

160 |

|

Operating press |

Mpa |

1.3 |

1.3 |

|

Operating temp |

℃ |

120~135 |

120~135 |

|

Heating power |

KW |

228 |

280 |

|

Customization can be made according to the actual needs of customers |

|||

Post time: Mar-18-2025