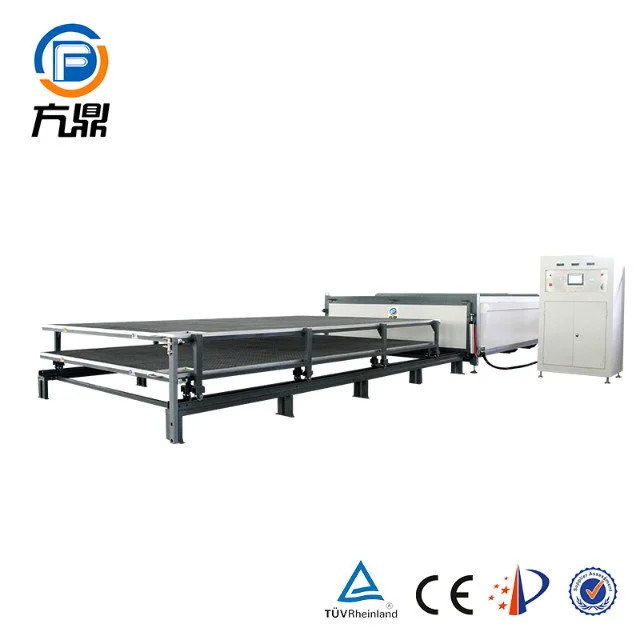

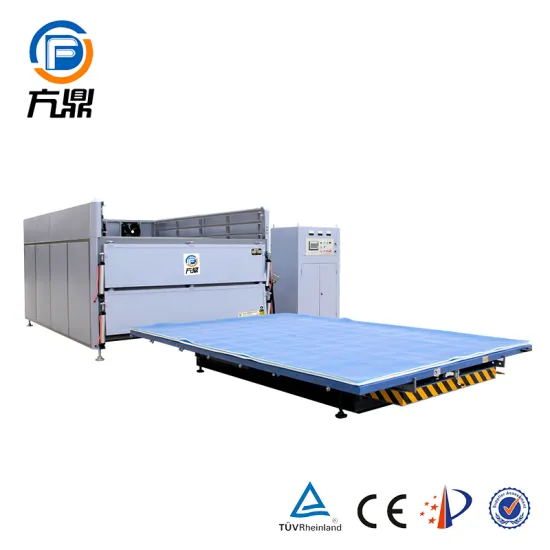

Manufacturer of Glass Kiln - Fangding Machine Process Laminated Glass with EVA/Sgp/TPU Film – Fangding

Manufacturer of Glass Kiln - Fangding Machine Process Laminated Glass with EVA/Sgp/TPU Film – Fangding Detail:

Basic Info.

| Model | FD-J–2-2 |

| Machine name | EVA glass lamination machine |

| Process Max. Glass size | 2000x3000mm |

| Specification | Double layers |

| Operation system | Siemens PLC |

| Power | 33KW |

| Net weight | 2200KGS |

| Dimension | 2600x4000x1150mm |

| Yield | 36 square meter per cycle |

| Origin | China |

| Warranty period | 1 year |

| Heating method | Forced convection |

| Application | Architecture/decorative/PDLC/LED |

Fangding Lamination Machines

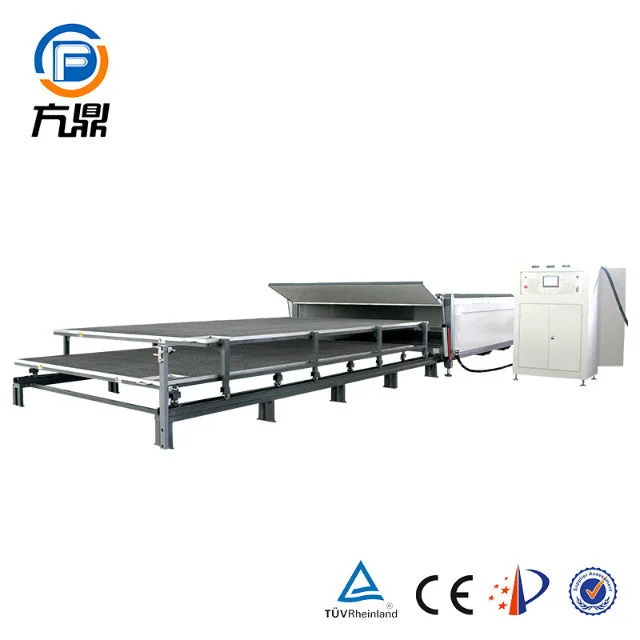

Since 2003, Fangding begin producing glass laminating machine, keep improving and inovation, using unique design of heating and vacuum systems, the heating is evenly in the heat box, temperature difference is 3-5 degrees. The glass laminating machine has two heating rooms. Make the production very smart , heating more quickly, saved around 30% engergy comparing to other Chinese machines.

EVA glass laminating machine can produce laminated glass without autoclave. Besides architecture clear laminated glass, the machine can also work with silk, paper, plastic film, metal mesh, fiber mesh, switchable film and many other materials for indoor decorative application.

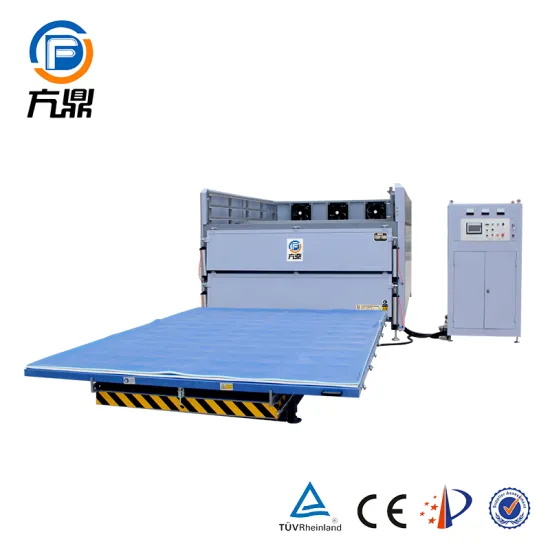

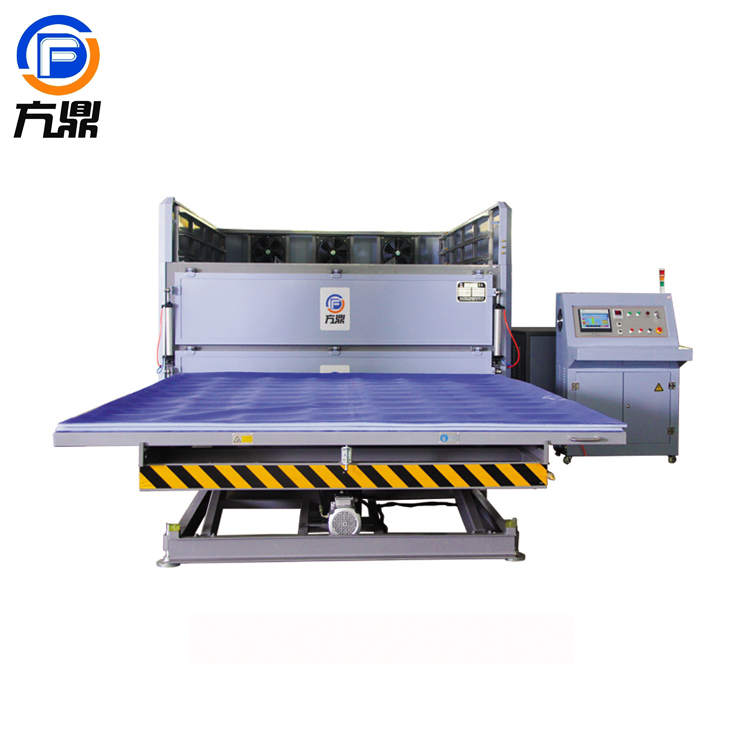

Heating Elements:

The heating elements are placed in the furnace evenly and resonable. The heating is provided with electric radiant heat and is evenly distrubuted with the assisstance of convection fan for very precise heating. This setup will quickly reach the target temperature, the temperature difference is bellow 5 degrees, the heating is evenly, the laminate glass quality is excellent.

1. The entire equipment frame is welded with 8-10mm thick high-strength steel, and the inner and outer layers are filled with high-density integrated insulation materials.

2. The equipment heating system is developed by our company. The high-performance heating elements are reasonably distributed in the furnace. The unique temperature compensation design allows the heat generated to be evenly distributed to all parts of the insulation box. Multi-point temperature detection of thermal sensing elements, intelligent directional heating, and temperature difference control at 3-5 ° C. The design not only features uniform heating and rapid heating, but also has a long service life and is not easily damaged.

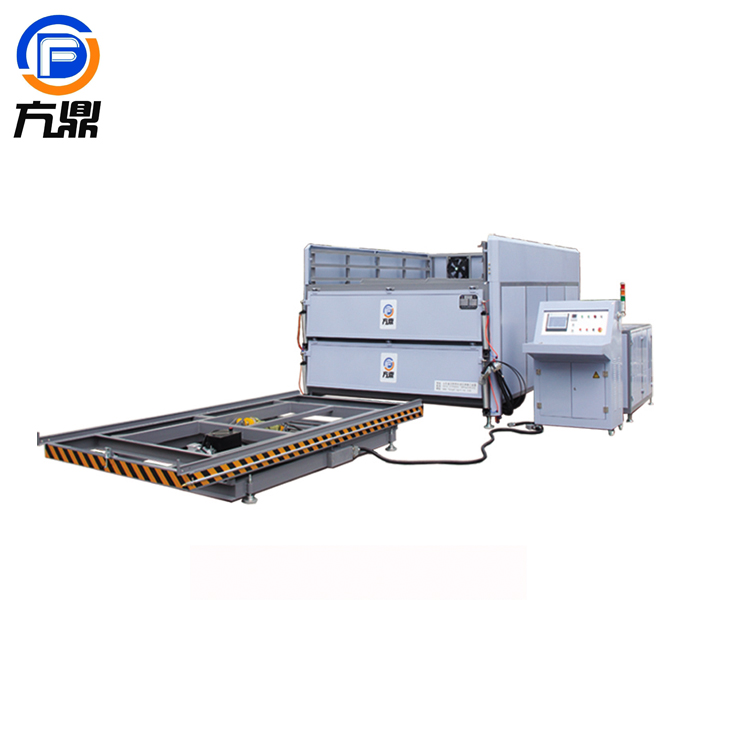

3.Vacuum system. Vacuum degree can be set in sections, pressure relief alarm, stable performance, with vacuum pressure holding, power failure protection and other functions.

4.The control system adopts a new humanized UI interface, which has a higher degree of automation, multi-functional computer control, and equipment status visualization throughout the process, adding fault alarms, regular maintenance tips, pressure relief alarms and other functions.

5.The glass carrier is composed of a deflection rail and a tray. A silicone bag is placed on the tray, and the glass is placed inside the silicone bag.

After-Sales Service:

Installation and technical training:

If the buyer needs the seller to install the machine and offering the technical training to the factory. The buyer need pay for

the sellers air ticket, hotel, food and so on the basic cost. Installation service is free.

Quality Warranty:12 months.(during the time, if any broken any spare parts, we will send for free, only

the shipping cost is on customer’s charge)

Shipping to Canada & USA & India

Machine main configeration

1)Siemens PLC control

2)One heating rooms

3)Two plates/layers

4)One set vacuum systems

5) One set PLC system

5)One ground rail

6)Two sets vacuum bags

7)Teflon Mesh: 2 sets

Special desgin avaliable

We are a leading manufacture in China with more than 18 years experience in glass laminated machine field. We have professional R&D and production team, if you have any special requirements, please contact with us freely. And warmly welcome you to visit us!

Product detail pictures:

Related Product Guide:

We are proud of the superior customer gratification and wide acceptance due to our persistent pursuit of top of the range both of those on merchandise and service for Manufacturer of Glass Kiln - Fangding Machine Process Laminated Glass with EVA/Sgp/TPU Film – Fangding, The product will supply to all over the world, such as: Luxemburg, Seychelles, Spain, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.