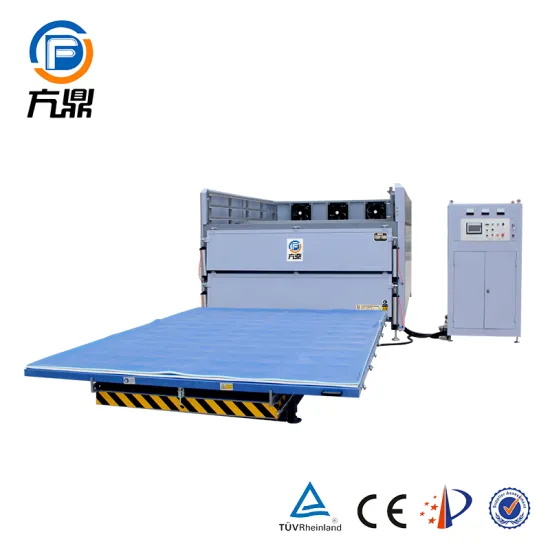

Manufacturer for Sandwich Glass Forming Furnace - Heat soak furnace – Fangding

Manufacturer for Sandwich Glass Forming Furnace - Heat soak furnace – Fangding Detail:

| TECHNICAL PARAMETER | ||||||

| Model | Operation system | MAX processing glass size(mm) | Holding Time(h) | processing capacity(KG/cycle) | Power(KW) | Dimension( mm) |

| FD-HF2045 | Siemens PLC | 2000×4500 | 1-4 | 3000 | 300 | 7100×2500×3000 |

| FD-HF2050 | Siemens PLC | 2000×5000 | 1-4 | 4000 | 380 | 7600×2500×3000 |

| FD-HF2560 | Siemens PLC | 2500×6000 | 1-4 | 6000 | 540 | 8600×2500×3500 |

| FD-HF2580 | Siemens PLC | 2500×8000 | 1-4 | 8000 | 715 | 10600×2500×3500 |

| FD-HF2860 | Siemens PLC | 2800×6000 | 1-4 | 7500 | 540 | 8600×2500×3800 |

1.Uniform temperature

(Finned heating tube,32 heating tubes are distributed in two rows on the top of the furnace,heat fast and evenly)

2.Real time monitoring

(There are 16 thermocouples in the furnace, 6 of which are evenly fixed on both sides of the furnace, and the other 10 are used to monitor the glass temperature in real time. )

3.Good heat preservation

(The heat-insulation system adopts seamless welding,minimize the passage of heat.)

4.Easy system operation

(It can be linked to WiFi remote monitoring and one button printing)

6.Air duct thermal cycle

(Unique air duct design,close the door, open the fan to heat, hot air through the upper air duct to the doorway air duct, sucked into the furnace by the fan, continuous stable circulation heating)

Product detail pictures:

Related Product Guide:

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Manufacturer for Sandwich Glass Forming Furnace - Heat soak furnace – Fangding, The product will supply to all over the world, such as: St. Petersburg, Plymouth, venezuela, On today, we've got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We've been looking forward to doing business with you!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.