Leading Manufacturer for Eva Film Interlayer - Newest Design Fangding Glass Laminate Machine (4 LAYER) on Promotion – Fangding

Leading Manufacturer for Eva Film Interlayer - Newest Design Fangding Glass Laminate Machine (4 LAYER) on Promotion – Fangding Detail:

Basic Info.

| Model NO. | FD-J-2-4 |

FANGDING Laminating Machines

Since 2003, Fangding begin producing glass laminating machine, keep improving and inovation, we use unique design of heating and vacuum systems, the heating is evenly in the heat box, temperature difference is less than 3 degrees. The glass laminating machine has two heating rooms, each room has independent control systems.Make the producing very smart , heating more quickly, saved around 30% engergy comparing to other Chinese machines.

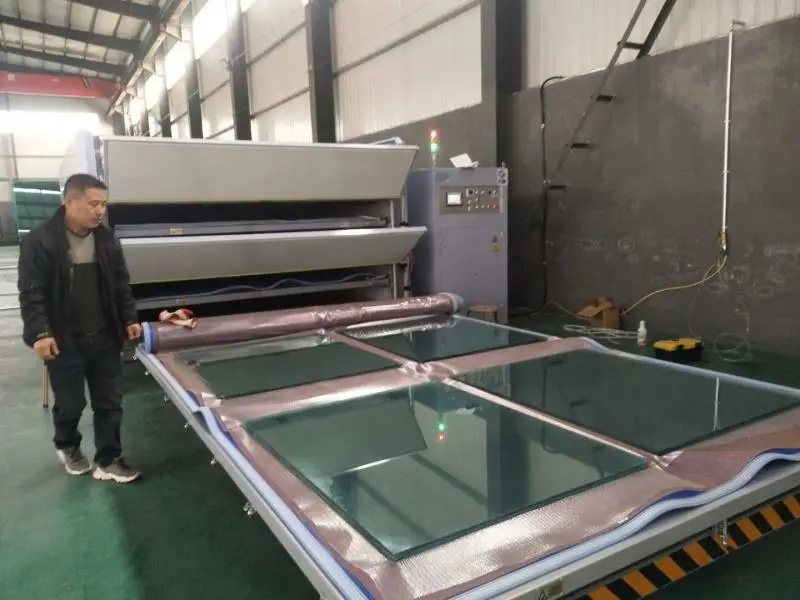

EVA laminating glass machine can produce laminated glass withou the use of and autoclave. The machine can work with silk, paper, plastic film, metal mesh, fiber mesh, switchable film and many other decorative film.

Heating Elements:

The heating elements are placed in the furnace evenly and resonable. The heating is provided with electric radiant heat and is evenly distrubuted with the assisstance of 2 convection fans for very precise heating. This setup will quickly reach the target temperature, the temperature difference is bellow 3 degrees, the heating is evenly , the laminate glass quality is excellent.

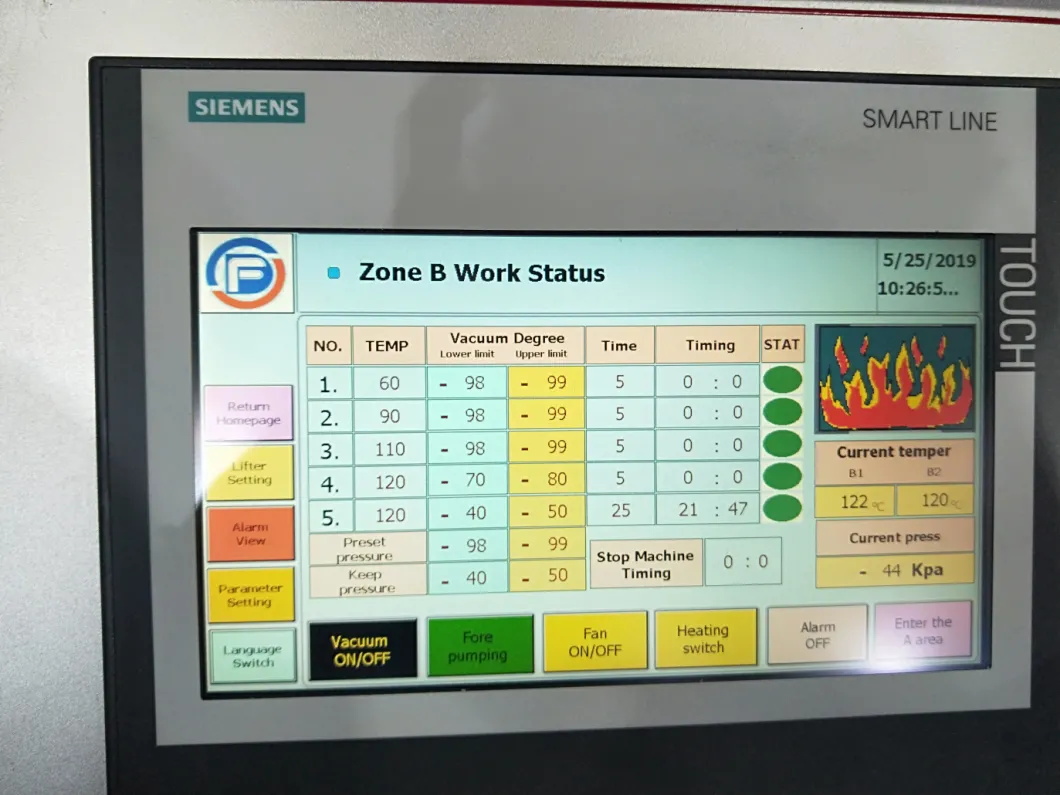

PLC control system:

Our four layers machine use two independent PLC systems.

All machines functions are controlled via PLC touch screen controls. All parameters can be easily set and adjusted for quick operation for many different types of applications. The PLC also controls the temperature which is regulated by means of adjusting voltage to the heating element, resulting in very accurate temperature control.

A unique advantage of the Fangding glass laminating machine is that you can producing different kinds of laminating glass in the same time, since it has two indepent working chamber.

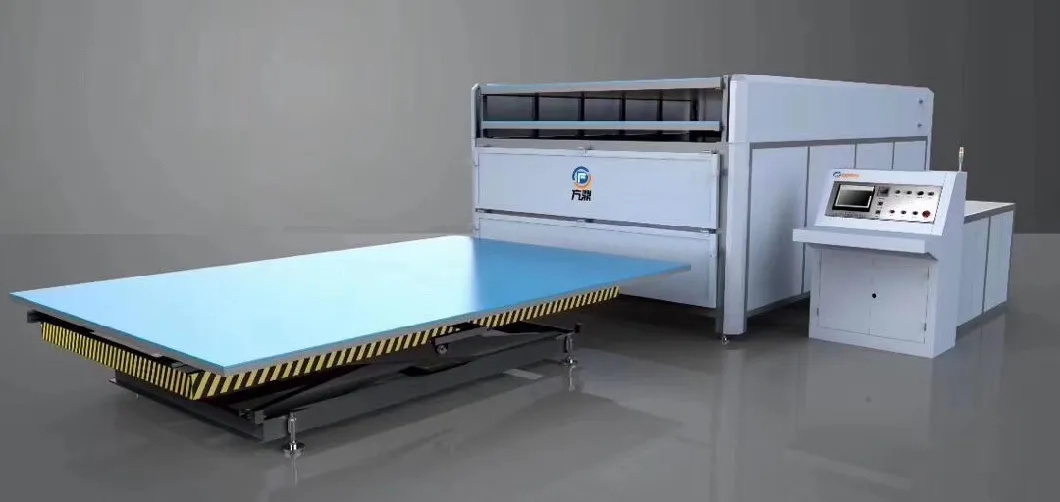

PRODUCT NAME: Fangding EVA glass laminating machine

ITEM#: FD-J-2-4

MAIN TECHNICAL PARAMETERS:

POWER INPUT: 220-480V THREEPHASE ALTERBATING CURRENT

POWER CONSUMPTION:38KW / H

MAX PROCESSING GLASS SIZE: Max size (mm): 2000 mm*3000mm

Max Arch height (mm): 400 mm(can design as your requirement even higher)

Max Thickness (mm): 36 mm

EFFICIENCY: Forming cycle (minute/furnace): 75-90min

Max processing area (M2 /furnace): 72M2

OPERATION SYSTEM: PLC, Man machine conversation.

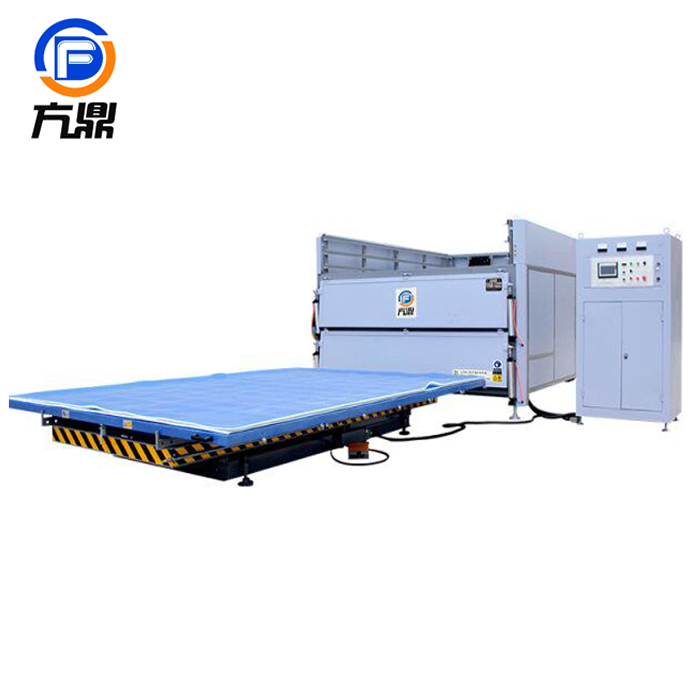

OPERATION PLATEFORM: 4 layers

WORKING TEMPERATURE: 90-140 0C

MACHINERY OUTSIDE DIMENTION :2530mm*4000mm*2150mm

N.W: 3700kgs

Machine main configeration

1). Siemens PLC control

2). Two heating rooms

3) Four plates/layers

4). Two sets vacuum systems

5) Two sets PLC system

5). One set loading lifter

6). Four sets vacuum bed

7). Teflon Mesh:4 sets

Special desgin avaliable

We are leading manufacture in China with more than 17 years experience in glas laminated manufacture machine field.We have research team with 8 employees, if you have any special requirement ,contact with us freely.And warmly welcome you to visit us!

Product detail pictures:

Related Product Guide:

We generally continually give you quite possibly the most conscientious shopper company, and the widest variety of designs and styles with finest materials. These endeavours include the availability of customized designs with speed and dispatch for Leading Manufacturer for Eva Film Interlayer - Newest Design Fangding Glass Laminate Machine (4 LAYER) on Promotion – Fangding, The product will supply to all over the world, such as: Madras, Australia, Iran, Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!