Good User Reputation for China EVA Laminated Furnace for Glass

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Good User Reputation for China EVA Laminated Furnace for Glass, Trust us and you will gain a lot more. You should truly feel totally free to make contact with us for additional data, we assure you of our greatest notice at all times.

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for China Laminated Glass Machine, Laminated Glass Furnace, With the enterprising spirit of” high efficiency, convenience, practicality and innovation”, and in line with such serving guidance of “good quality but better price, ” and “global credit”, we’re striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

Specification:

| Model | Processing glass size (mm) | Rated power | Operation system | N.W. | Outside dimonsion (mm) | Floor space (mm) | Production capacity (m2/cycle) |

| FD-J-2-2 | 2000*3000*2 layers | 26kw | Siemens PLC | 2200kgs | 2600*4000*1150 | 3700*9000 | 36 |

| FD-J-3-2 | 2200*3200*2 layers | 28kw | Siemens PLC | 2400kgs | 2750*4200*1150 | 4000*9500 | 42 |

| FD-J-4-2 | 2200*3660*2layers | 30kw | Siemens PLC | 2500kgs | 2750*4600*1150 | 4000*10500 | 48 |

| FD-J-5-2 | 2440*3660*2layers | 33kw | Siemens PLC | 2600kgs | 2980*4600*1150 | 4500*10500 | 53 |

| Place of Origin | Shandong, China |

| Voltage | 220/380/440V, can be customized |

| Certification | CE, CSA,UL |

| Warranty | 1 Year |

| After-sale service | Online support, Free spare parts, Field installation, commissioning and training, Video technical support |

| Glass Thickness | 3-19mm |

| Core Components | Motor, heating tube, PLC, Pump |

| Product name | EVA Glass Laminating Machine |

| Operating temperature | 90-140℃ |

| Control system | PLC |

| PLC | Siemens Brand |

| Heating method | Forced Convection |

| Operation | Automatic Control |

| Processable glass type | Normal Glass |

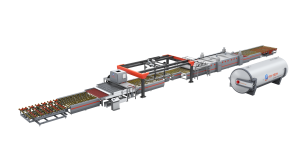

Fangding Latest 2-Layer glass lamination furnace

The glass laminating furnace adopts the principle of high temperature vacuum extraction. The film is placed in the middle of two or more pieces of glass. After the high temperature vacuum in the furnace, the film and glass are tightly bonded together to achieve good transparency and no bubbles. And there is no drop after breaking.

* Independent heating up and down, floor heating distribution, modular control, strong convection circulation of turbine

* A number of patented technologies.The heating system uses a turbine fan and a high-density explosion-proof stainless steel electric heating rod for heating. It is equipped with a temperature sensing device, a modular area heating control, intelligent self-adjusting temperature, fast heating, uniform temperature, and strong turbo fan. Convection circulation to ensure the temperature difference in the furnace within 5 degrees.

* The insulation system adopts seamless processing to minimize heat loss. Compared with similar products and equipment, it can save energy by more than 30%.

* High-performance vacuum system with automatic vacuum pressure holding, stable working around the clock, improving product efficiency and quality.

Features:

* 99% pass rate

* 50% energy saving

* High efficiency

* PLC control, Simple to operate

* High quality spare parts

* EVA/TPU/SGP film as interlayer

* Rich range of products

* Large size bending glass processing

* No waste when suddenly power off

* Free home installation and training

Company

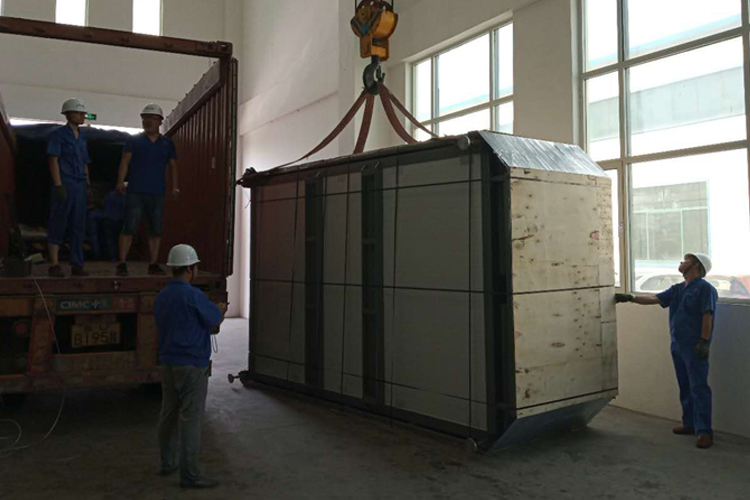

Fangding Technology Co., Ltd is a high-tech enterprise which was founded in October 2003, located in Taoluo industrial park, Donggang district, Rizhao city, covering an area of more than 20,000 square meters, with a registered capital of 100 million yuan, specializing in R&D, production and sales & service of the laminated glass machinery and the interlayer films, the main products are EVA laminated glass machine, Heat Soak Furnace, Smart PVB glass laminating line and EVA, TPU and SGP films.

The company has a large number of skilled senior technical personnel and experienced management personnel, established cooperation with many scientific research institutions, has been committing to provide full set of solutions of the glass laminating for the deep-processing enterprises; the company has reached co-operations with many global top 500 companies.

In the international market, the products has been exported to Asia, Europe, America and other more than 68 countries and regions. Be responsible for the customers and develop together with them! It has laid a solid foundation for enterprises to compete on the international stage. Our company has won the trust and praise from the customers all over the world for years.

Looking at the world and advancing with the times, we focus on the details and refine the quality. We gather bits and pieces to chase the future. Fangding Technology uses the passion of innovation to ignite the development of high-end technology enterprises of China.

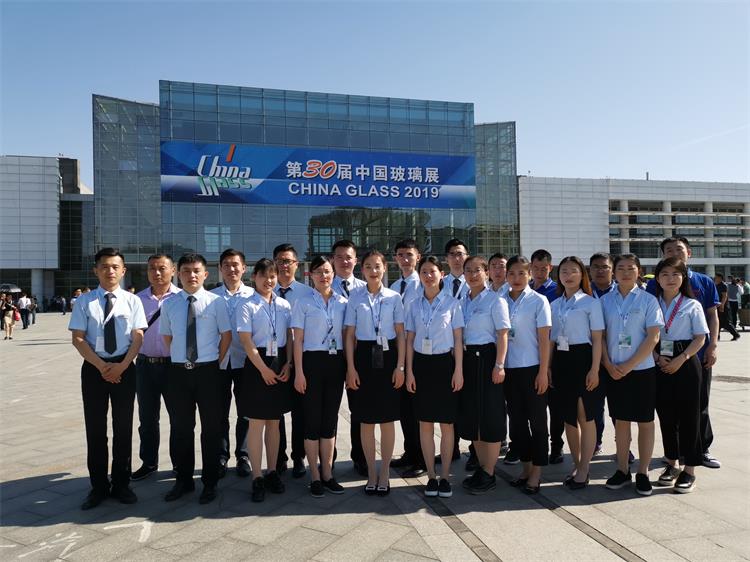

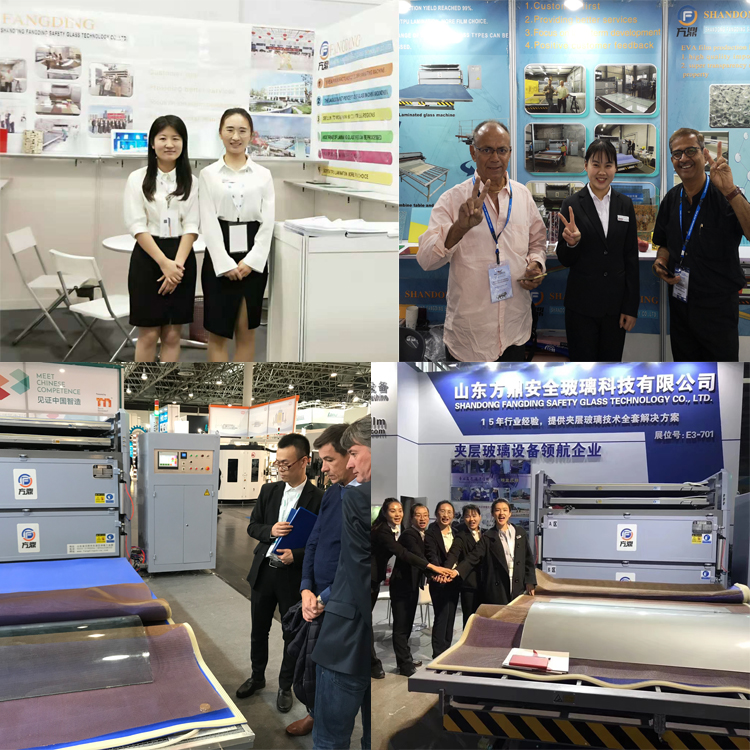

Exhibition

The company participated in the world glass industry well-known exhibitions every year, such as Germany Dusseldorf international glass industry exhibition, China international glass industry exhibition, China international window and curtain wall exhibition, Italy Milan international glass industry exhibition, the Middle East (Dubai) international glass exhibition, the United States Atlanta international window and curtain wall exhibition and other exhibitions.

During the exhibition, through the on-site processing of the laminated glass, Fangding presented its unique design style and manufacturing process to the customers!

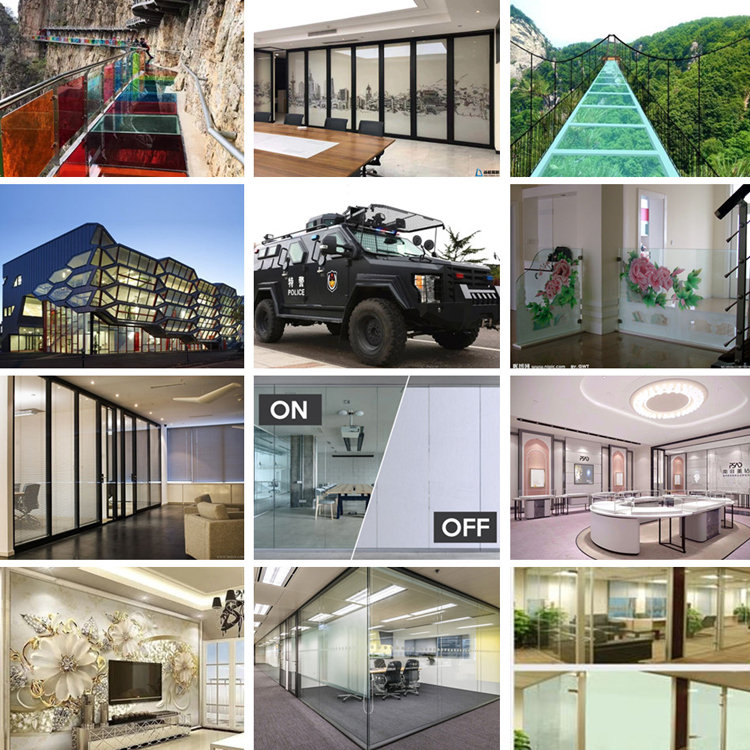

Application

Outdoor architecture glass and indoor decorative glass, including glass wall, ordinary float laminated glass, curved laminated glass, tempered laminated glass, high-level office building, furniture, church, villa, wall windowpane, tabletop, craft glass, colored laminated glass, LED glass, smart glass, bullet-proof glass, multi-layer laminated glass, laminated silk glass, household appliances panel glass, glass corner, background wall and video wall glass, coffee table surface glass, partition screen, frameless painting laminated glass and personalized portrait glass etc.

What is Laminated Glass Used For?

Laminated glass is both transparent and reinforced, a unique combination of features that make it ideal for a variety of applications. The material, depending on its specific makeup, can resist impact, dampen sound, filter UV radiation, and withstand heat. These characteristics offer numerous advantages, including:

Safety: Laminated glass is impact resistant, protecting buildings and vehicles from break-ins, bullets, and inclement weather. If an object does break the glass, the glass does not shatter because it’s attached to the interlayer material.

Versatility: The many characteristics and configurations of laminated glass make it a versatile building material. Designers can use laminated glass in both flat and curved applications with varying opacity, as well as meet other application requirements.

Clarity: Depending on the application, transparency and visual clarity remain just as important as other features of laminated glass. With the right interlayer material, laminated glass has little visual distortion.

Thanks to these advantages, engineers, architects, and other design professionals rely on laminated glass across industries. Laminated glass is used in architecture for windows, skylights, and walls. The material is also used in the automotive, aerospace, marine, and solar industries.