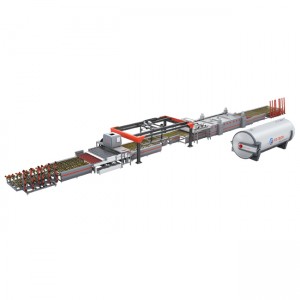

PVB automatic glass laminating line

FANGDING TECHNOLOGY CO., LTD

LAMINATED GLASS

PRODUCTION LINE

AUTOCLAVE

THE PREFERRED EQUIPMENT FOR

GLASS LAMINATING LINE

--TO PROVIDE YOU WITH HIGH-QUALITY PRODUCTS --

Quailty

Assurance

High quality

hardware

Exquisite

craftsmanship

Perfect after-sales

service

PRODUCT DETAILS

-- RELIABLE QUALITY AND ASSURED PURCHASE. --

| Model | FD-L2500 |

| Machine name | PVB laminated glass production line |

| Brand | FD |

| Process Max. Glass size | 2500x6000mm |

| Process Min. Glass size | 400x600mm |

| Specification | 2500mm line with 2850x6000mm autoclave |

| Operation system | Siemens PLC |

| Power | 540KW |

| Net weight | 45000KGS |

| Floor space | 63000x8000mm |

| Yield | 400-600 square meter per cycle |

| Origin | China |

| Warranty period | 1 year |

| Heating method | Forced convection |

| Application | Architecture/Decoration/Aerospace/Bulletproof |

| No | Item | Model | Remarks |

| 1 | Full-automatic mechanical loading station | FDSP25A | double-arm turn-over loading station, running speed: 0-20m/min |

| 2 | Glass cleaning and drying | FDQX25A | can clean low-e glass No load operation, energy saving and low noise |

| 3 | Side-push positioning conveyor | FDDW25 | accurate positioning, Stack error accuracy ≤ 0.5mm |

| 4 | open-close type assembling table. | FDHP25 | accurate ,adjustable speed, can adapt to various states of glass assemble. |

| 5 | High precision automatic suction hanger | FDGD25A | Automatic moving suction Servo motor control,Precise positioning, no trace on glass, 40-60m /min adjustable speed of .Each suction cup is equipped with an air valve control. |

| 6 | Pre-press machine | FDGY25 | independent roller press, medium wave infrared heating, three heating sections, (each section is 2 meters).Forced convection cycle heating. |

| 7 | Unloading machine | FDXP25 | mechanical unloading glass |

| 8 | Autoclave | FD-G2860 |

forced convection cycle

(inner diameter 2860) Can produce 2.5MX6 meters of glass |

FULL AUTOMATIC LAMINATED GLASS PRODUCTION LINE

PRODUCT FORM

1. The automatic glass loading machine

2. The multi-functional glass washing & drying machine

3. High precision glass positioning conveyor

4. The double station glass combining machine

5. The automatic movable suction cup hanger

6. The horizontal 3-roller film storage machine

7. The frequency conversion transition conveyor

8. The infrared roller pressing machine

9. The flip-type glass unloading machine

10. The glass autoclave

TECHNICAL FEATURES

1. All parts of the whole line adopt PLC centralized control system, frequency conversion, 3 sets of HMI interface operation.

2. The special purpose part is equipped with encoder and servo motor to ensure stability and processing accuracy during production. The whole machine runs smoothly and reliably.

3. The whole production line is designed with high efficiency, energy saving, environmental protection, lower noise and other features.

4. Each part of the whole line can realize communication function with its neighboring parts,which is convenient to control and easy to operate.

5. The whole line adopts Siemens PLC centralized control system, main configurations are equipped with Delta Transducer and Schneider/Chint electrical components.

6. The whole line can realize automatic operation, labor-saving, safe and reliable, high efficiency and low energy consumption.

INTELLIGENT LAMINATED GLASS PRODUCTION LINE

PRODUCT FORM

1. Glass washing & drying machine

2. Glass positioning conveyor or Glass taking conveyor(Alternative)

3. Double station glass combining machine

4. Semi-automatic suction cup hanger

5. The horizontal 3-roller film storage machine

6. Transition conveyor

7. Roller pressing machine

8. Glass autoclave

TECHNICAL FEATURES

1. The washing machine has a solid structure, beautiful appearance, energy-saving design, equipped with shutdown protection function, and an independent wind-supply system to make the glass more cleaner.

2. Glass positioning conveyor, with fast positioning speed and high precision performance, suitable for the large pieces of glass production.

3. Double-station glass combining machine, composed of front and rear stations, which is convenient for glass combination and film cutting, and can be operated by manually and automatically.

4. The suction cup of the hanger adopts special materials to ensure that no traces are left on the glass surface, so as to ensure the production of high-quality products.

5. The horizontal 3-roller PVB/SGP film storage machine is equipped with automatic film releasing and rolling up functions, and this design makes the film replacing work more faster and convenient.

6. The transition conveyor is designed with the best synchronous, smooth and fast production performance.

COMPANY PROFILE

AFTER-SALES

SERVICE CAPABILITY

SINCERE

QUALITY

STRONG

PRICE

R & D TECHNICAL TEAM

01 Technical seminar

02 Drawing calculation

03 Detail communication

04 Experienced

QUALIFICATION

CERTIFICATE

EXHIBITION STYLE

CUSTOMER REVIEW

The equipment is sold to varous countries and has received unanimous praise from customers.

CONTACT US

Jennifer Zhu

HOT LINE +86-18906338322

Website: https://en.fangdingchina.com/

Email: sales2@foundite.com

Add: Huifeng Road, Taoluo Industrial Park, Donddang District, Rizhao City, Shandong Province, China