Full Automatic Laminating Glass Production Line with Autoclave

FANGDING TECHNOLOGY CO., LTD

LAMINATED GLASS

PRODUCTION LINE

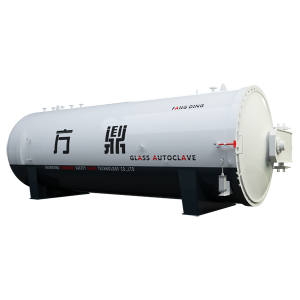

AUTOCLAVE

THE PREFERRED EQUIPMENT FOR

GLASS LAMINATING LINE

--TO PROVIDE YOU WITH HIGH-QUALITY PRODUCTS --

Quailty

Assurance

High quality

hardware

Exquisite

craftsmanship

Perfect after-sales

service

PRODUCT DETAILS

-- RELIABLE QUALITY AND ASSURED PURCHASE. --

FULL AUTOMATIC LAMINATED GLASS PRODUCTION LINE

We provide a full range of laminated glass equipment solutions. Specifications and configurations are optional, tell us your specific requirements, and we will tailor the optimal solution for you.

|

Production |

Full Automatic Laminated Glass Production Line with Autoclave |

|

Machine Model |

FD-A2500 |

|

Rate Power |

540KW |

|

Processing glass size |

Max glass size:2500*6000mm Min glass size:400*450mm |

|

Glass thickness |

4-60mm |

|

Voltage |

220-440V50-60Hz3-phaseAC |

|

Working period |

3-5h |

|

Working temperature |

60-135℃ |

|

Net weight |

50t |

|

Operation system |

Siemens PLC centralized control |

|

Productivity |

300-500m/cycle |

Process Flow

After passing by Automatic mechanical single arm glass laoding machine,the frequency conversion transition conveyor A,the multifunctional glass washing and drying machine,the high precision glass positioning conveyor,the double station glass combining machine,the automatic movable suction cup hanger, the 6-roller film storage machine,the frequency conversion transition conveyorB,the infrared roller pressing machine,90 degree two-way position table ,Gantry glass unloading machine in a horizontal way,the glass processed as semi-finished laminated glass,and then finished glass is pocessed by the autoclave.

TECHNICAL FEATURES

1. All parts of the whole line adopt PLC centralized control system, frequency conversion, 3 sets of HMI interface operation.

2. The special purpose part is equipped with encoder and servo motor to ensure stability and processing accuracy during production. The whole machine runs smoothly and reliably.

3. The whole production line is designed with high efficiency, energy saving, environmental protection, lower noise and other features.

4. Each part of the whole line can realize communication function with its neighboring parts,which is convenient to control and easy to operate.

5. The whole line adopts Siemens PLC centralized control system, main configurations are equipped with Delta Transducer and Schneider/Chint electrical components.

6. The whole line can realize automatic operation, labor-saving, safe and reliable, high efficiency and low energy consumption.

INTELLIGENT LAMINATED GLASS PRODUCTION LINE

PRODUCT FORM

1. Glass washing & drying machine

2. Glass positioning conveyor or Glass taking conveyor(Alternative)

3. Double station glass combining machine

4. Semi-automatic suction cup hanger

5. The horizontal 3-roller film storage machine

6. Transition conveyor

7. Roller pressing machine

8. Glass autoclave

Product Update

In the updated product, we have added automatic mechanical single arm glass loading machine,it is PLC centralized control and the two largest types of glass, A Max glass processing size 3300 * 6100 and B Max glass processing size 2500 * 3700.And 90 degree two-way position table,Its advantages are Frequency conversion speed regulation ,the whole line cooperates with uniform speed,evenness,rhythm,and two-way position.The last one was added gantry glass unloading machine,its advantages are use servo control to accurately place glass and achieve automation.

COMPANY PROFILE

Fangding Technology Co., Ltd. was established in October 2003 and is located in Taoluo Town Industrial Park, Donggang District, Rizhao City. It is a high-tech enterprise specializing in the research and development, production, sales, and service of laminated glass equipment and laminated glass intermediate films. The company's main products include EVA laminated glass equipment, intelligent PVB laminated glass production line, high-pressure reactor, EVA, TPU, SGP intermediate film. Looking at the world and keeping pace with the times, our company, Fangding Technology, focuses on details, condenses quality, gathers small details, and pursues the dream of the future. Fangding Technology ignites the development path of China's high-end technology enterprises with innovative passion.

AFTER-SALES

SERVICE CAPABILITY

SINCERE

QUALITY

STRONG

PRICE

R & D TECHNICAL TEAM

01 Technical seminar

02 Drawing calculation

03 Detail communication

04 Experienced

QUALIFICATION

CERTIFICATE

EXHIBITION STYLE

Exhibition

The company participated in the world glass industry well-known exhibitions every year, such as Germany Dusseldorf international glass industry exhibition, China international glass industry exhibition, China international window and curtain wall exhibition, Italy Milan international glass industry exhibition, the Middle East (Dubai) international glass exhibition, the United States Atlanta international window and curtain wall exhibition and other exhibitions.

During the exhibition, through the on-site processing of the glass processing, Fangding presented its unique design style and manufacturing process to the customers!

CUSTOMER REVIEW

The equipment is sold to varous countries and has received unanimous praise from customers.

CONTACT US

Jennifer Zhu

HOT LINE +86-18906338322

Website: https://en.fangdingchina.com/

Email: sales2@foundite.com

Add: Huifeng Road, Taoluo Industrial Park, Donddang District, Rizhao City, Shandong Province, China