Factory Outlets Top Grade Glass Lamination Machine - PVB automatic glass laminating line – Fangding

Factory Outlets Top Grade Glass Lamination Machine - PVB automatic glass laminating line – Fangding Detail:

Standard PVB laminated glass production line

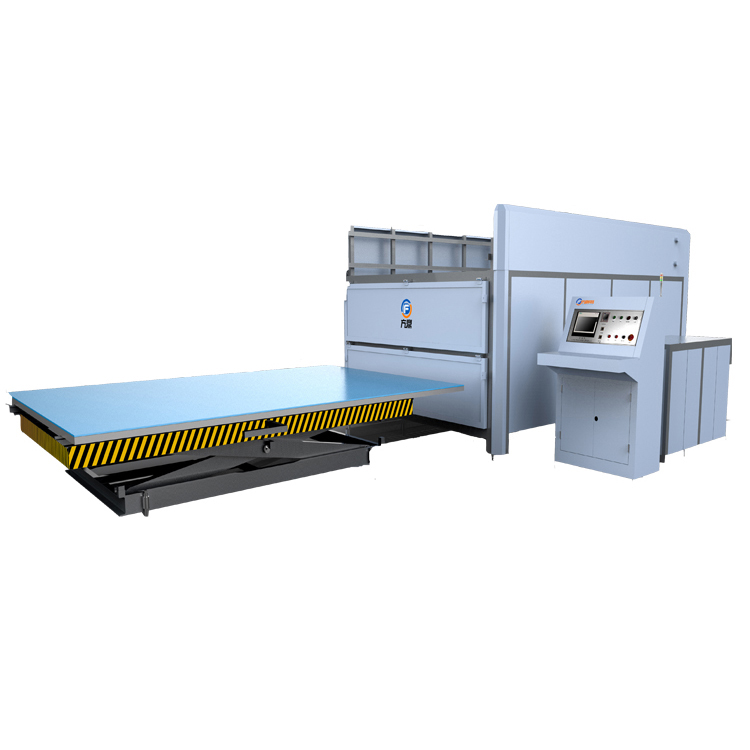

| Model | FDY2850 |

| Machine name | PVB laminated glass production line |

| Process Max. Glass size | 2500x6000mm |

| Specification | 2850mm |

| Operation system | Siemens PLC |

| Power | 232KW |

| Net weight | 25000KGS |

| Dimension | 11000x3400x3500mm |

| Yield | 400-600 square meter per cycle |

| Origin | China |

| Warranty period | 1 year |

| Heating method | Forced convection |

| Application | Architecture/Decoration/Aerospace/Bulletproof |

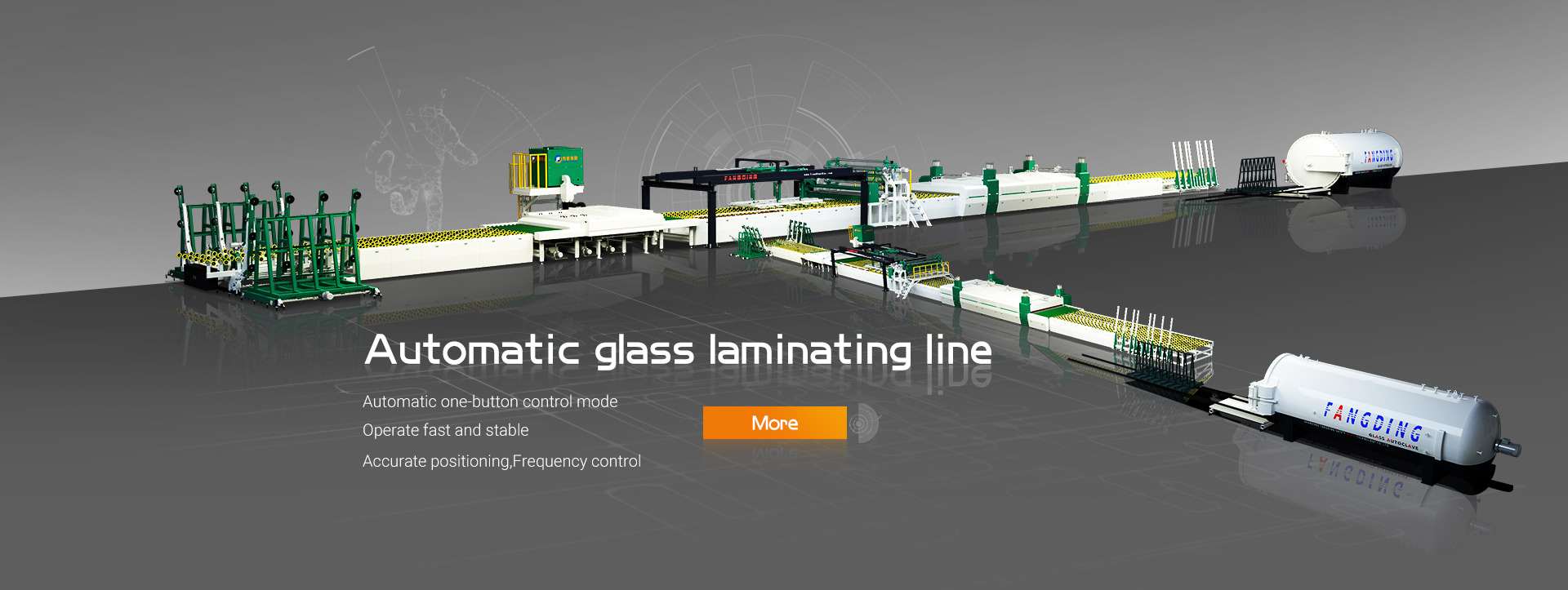

ZCKJ-2500A Full-Automatic Laminated Glass Production Line

1. All sections of the line adopt PLC centralized control systerm, frequency control and three HMI interface operations.

2. The special purpose segment is equipped with encoder and servo motor to ensure equipment stability and machining accuracy.

3. High efficiency, energy saving, environmental protection, noise and other special controls shall be considered in the whole line design.

4. The film spreading machine adopts automatic film placing and electric film returning.6 rolls of plastic film lay, easy to operate, easy to replace plastic film.

5. The structure of the initial press is reasonable, easy to operate.The whole machine runs smoothly and reliably, and is centrally controlled by the chip room.The heating area is evenly distributed, and domestic medium-wave infrared heating tube is adopted for heating. The temperature is measured and controlled in the zone, and the maximum temperature is 250℃(adjustable).

6. Adopt mechanical turnover unloading table to unload.

7. The glass autoclave is automatically controlled by PLC and operated by man-machine interface to achieve safety, reliability, high efficiency and energy saving.

8. Except for the monitoring of the operator at the loading and unloading stations, the operation of other lines is fully automatic, realizing intelligent production, reducing personnel risks and production costs.

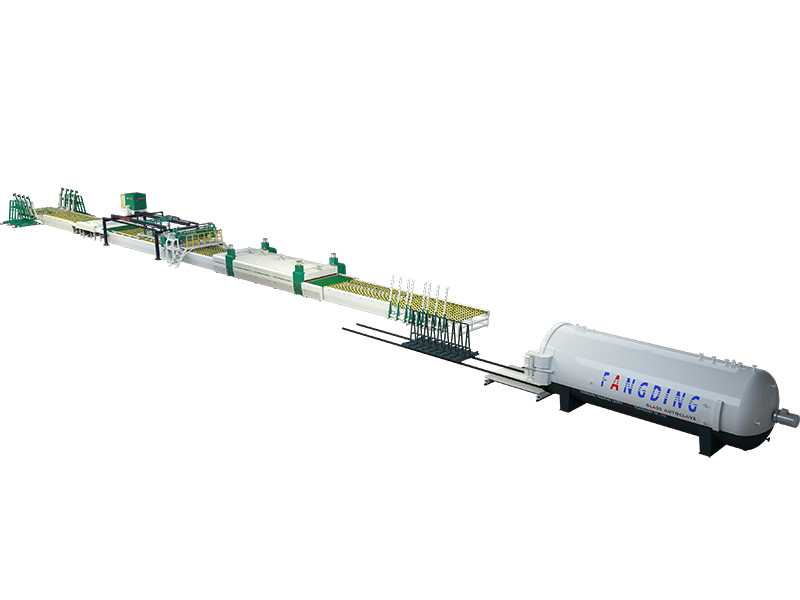

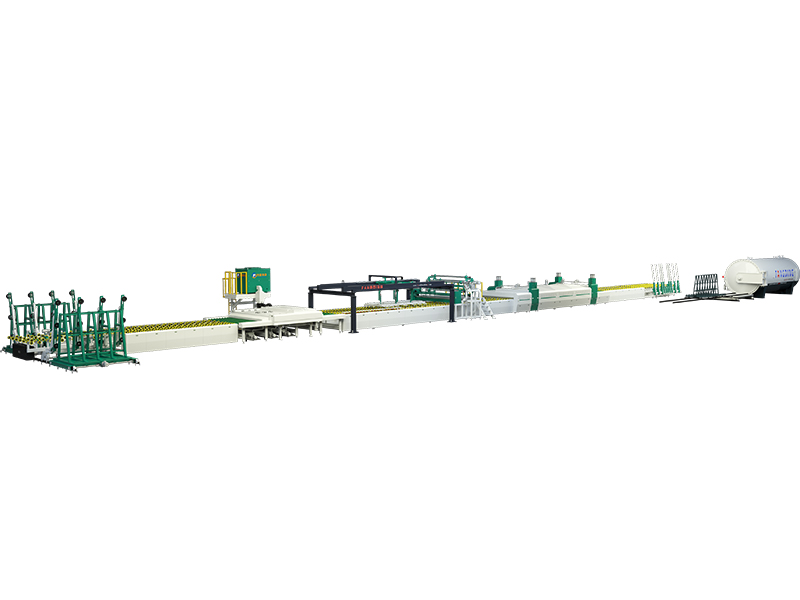

| No | Item | Model | Remarks |

| 1 | Full-automatic mechanical loading station | FDSP25A | double-arm turn-over loading station, running speed: 0-20m/min |

| 2 | Glass cleaning and drying | FDQX25A | can clean low-e glass No load operation, energy saving and low noise |

| 3 | Side-push positioning conveyor | FDDW25 | accurate positioning, Stack error accuracy ≤ 0.5mm |

| 4 | open-close type assembling table. | FDHP25 | accurate ,adjustable speed, can adapt to various states of glass assemble. |

| 5 | High precision automatic suction hanger | FDGD25A | Automatic moving suction Servo motor control,Precise positioning, no trace on glass, 40-60m /min adjustable speed of .Each suction cup is equipped with an air valve control. |

| 6 | Pre-press machine | FDGY25 | independent roller press, medium wave infrared heating, three heating sections, (each section is 2 meters).Forced convection cycle heating. |

| 7 | Unloading machine | FDXP25 | mechanical unloading glass |

| 8 | Autoclave | FD-G2860 |

forced convection cycle (inner diameter 2860) Can produce 2.5MX6 meters of glass |

Our company

Fangding Technology Co., Ltd is a high-tech enterprise which was founded in October 2003, located in Taoluo industrial park, Donggang district, Rizhao city, covering an area of more than 20,000 square meters, with a registered capital of 100 million yuan, specializing in developing, manufacturing and selling the laminated glass equipment and the interlayer films, the The main products are EVA laminated glass machine, Heat Soak Furnace, Smart PVB glass laminating line and EVA,TPU,SGP films.

The company participated in the world glass industry well-known exhibitions every year, such as Germany Dusseldorf international glass industry exhibition, China international glass industry technology exhibition, China international window and curtain wall exhibition, Italy Milan international glass industry exhibition, the Middle East (Dubai) international glass exhibition, the United States Atlanta international window and curtain wall exhibition and other exhibitions. During the exhibition, through the on-site processing of the laminated glass ,Fangding presented its unique design style and manufacturing process to the customers!

In the international market, the products has been exported to Asia, Europe, America and other more than 60 countries and regions .Be responsible for the customers and develop together with them!It has laid a solid foundation for enterprises to compete on the international stage.the company has won the trust and praise from the customers all over the world for years.

Workshop & Packing & Shipment

Product detail pictures:

Related Product Guide:

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for Factory Outlets Top Grade Glass Lamination Machine - PVB automatic glass laminating line – Fangding, The product will supply to all over the world, such as: Mali, Madagascar, kazan, Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we've got got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.