factory Outlets for Eva Laminated Glass Processing Machine - EVA Sgp TPU Glass Laminating Machine – Fangding

factory Outlets for Eva Laminated Glass Processing Machine - EVA Sgp TPU Glass Laminating Machine – Fangding Detail:

| Model NO. | FD-J-5-4 |

| Condition | New |

| Voltage | 220V/380V Customized |

| Forming Cycle | 90-120min/Cycle |

| Production Capacity in 8 Hours | 342sqm |

| Max Bending Deep | 400mm or Customized |

| Working Temperature | 90-150c |

| Net Weight | 4800kgs |

| After-Sales Service Provided | Home Installation and Technical Training |

| Trademark | Fangding |

| Specification | 2440×3660 |

| HS Code | 8475291900 |

| Grinding Head Number | 9 |

| Max Glass Size Processing | 2440*3660mm |

| Total Power | 58kw |

| Max Production Capacity in One Cycle | 107sqm |

| Max Glass Thickness in Each Silicone Bag | 40mm |

| Operation Platforms | 4 Trays |

| Floor Space | 4500*10500 |

| Warranty Time | One Year |

| After Warranty Service | Video Technical Support, Online Support |

| Transport Package | Density Fiber Board |

| Origin | Shandong, China |

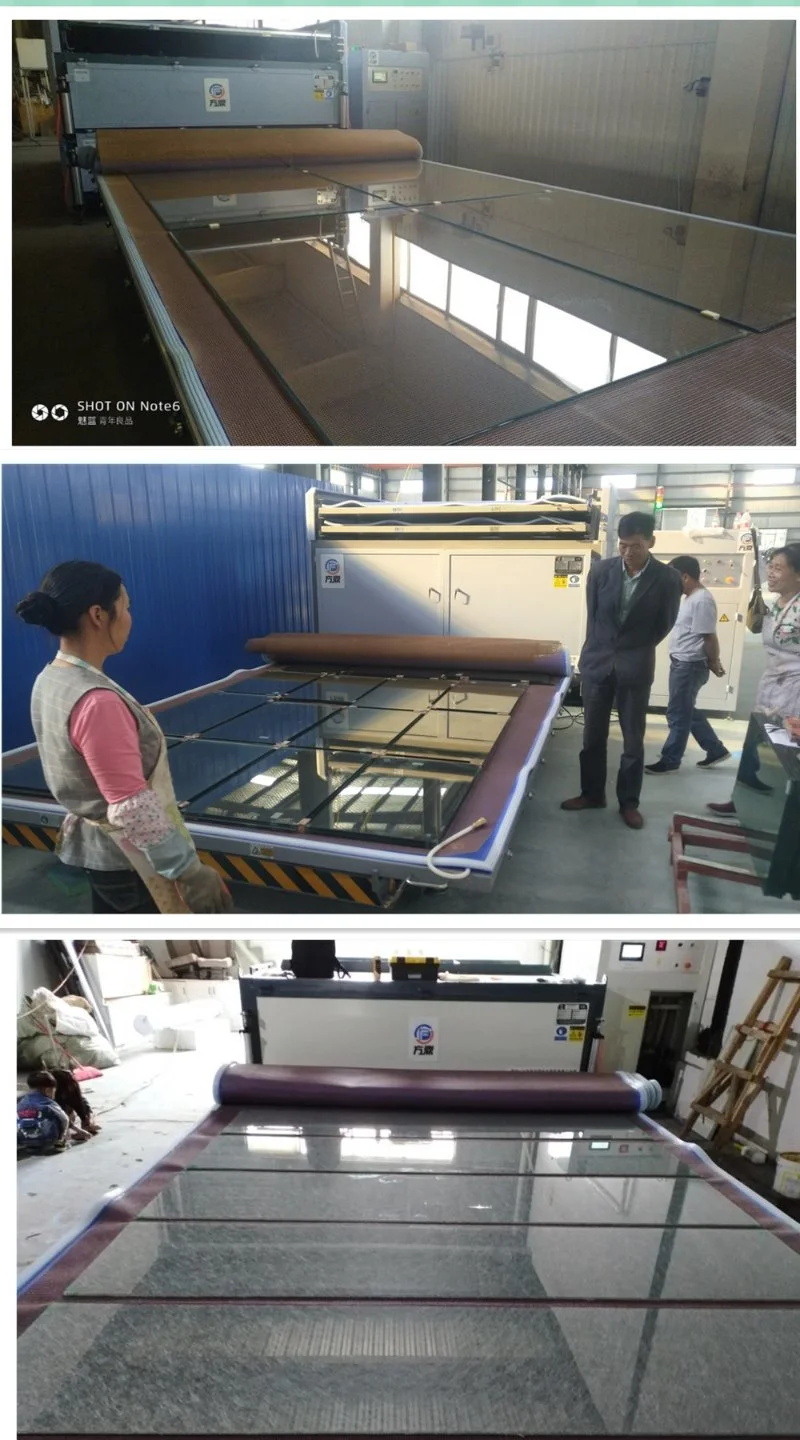

Fangding glass laminating machine adopt the principle of high temperature with vacuum, use EVA films as mainly interlayer to produce Architecture laminated glass, Curved tempered laminated glass, Top grade decorative laminated glass(Such as marble paper, silk, dry flower, acrylic, floor tile laminated glass etc…), Bulletproof laminated glass, PDLC/LED laminated glass etc.

Main features

* Process EVA/TPU/SGP laminated glass

* Product yield at least 99%

* Double independent systems

* Energy saving and small space

* Adopt advanced heating technology

* Only 0.5kw for 1 sqm of laminated glass

* Labor saving, 2 workers are enough.

* Selling to more than 60 countries®ions

* No clients’ complaint in recent 6 years

Technican data

The machine size is customized, below are several basic sizes.

| Machine model: | four floors laminated glass machine. |

| Rated power | 20+20/23+23/27+27/30+30KW |

| Processing glass size | Max:3000*2000/3200*2200/3660*2200/3660*2440mm |

| Max glass thickness 40mm | |

| Floor space | L*w:3720*9000/4020*9500/4020*10500/4520*10500mm |

| Working temperature | 90degree–150degree |

| Efficiency | 75-120min/cycle |

| Max production capacity:72/84/96/107sqm/cycle |

There are basiclly 3 models for choice according different machine sizes.

4 layers, 3 layers, 2 layers.

Machine description

1.Double independent system

Each part has it’s own control system.so can produce different kinds of glass at same time.

2).PLC control system

this system make all types of glass production can be set by the touch screen, it can be finished automatically.

3).Vacuum buffer tank

Adopt Germany technology vacuum pump, have vacuum buffer tank, it is water vapor separation system, not only have not waste product when suddenly power off, but also make vacuum pump longer service time.

4). Silicon bag

Special design high tear resistant silicon bag, import materials, which can stand glass accumulative ply 36 mm and longer service life, best sealing.

5). Five temperature section

Enable vacuum pressure set in, each section independently, multiple processing parameters can be set and saved.

6).Automatic lifting table

Add remote control and Omron limit switch, work like elevator, more safety and convenient.

7). Energy saving.

This kind of laminated glass production line can save 50% energy consumption for you than the similar products.

8).Bending laminated glass.

The only one laminated glass machine can produce large size bending laminated glass. the bending deep can reach 400mm.

9).Famous brand.

Every part of our machine is famous brand, Siemens or Schneider ensure best quality.

10).Famous brand.

Adopts advanced technolgies, vacuum pump maintenance reminder, cooling time reminder,

fault detection system, tripping function and humanized design, more automaticlly.

Accessories

| Spare parts | |

| Touch screen /touch panel | Siemens 10-inch touch screen |

| PLC Control System | Siemens PLC |

| Heating tubes | 304 stainless steel heating tube |

| Vacuum pump | Famous chinese brand or Busch |

| Lifting table | Independent R &D,Omron limit switch |

| Silicone bag | High tear / temperature resistant |

Packing & Shippment

We make strict Quality testing before packing by professional staff and engineer.

The machine packed with standard package, will be fixed firmly in the container.

It makes sure the machine arrived our customers’ factory with good condition.

Exibition & Customers

1.Fangding attend large exhibition both domestic and abroad every year!

2.We always make laminated glass in the glass fair, tempered laminated glass and bending laminated glass can be finished in one furnace.

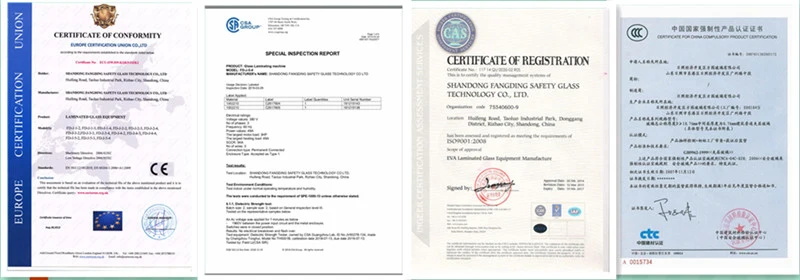

Certifications

Our machine have got CE certificate of European union, ISO9001 management system certificate. TUV certificate of Germany, CSA certification, UL certification for Amercian markets.

Have 12 Independent R&D patent.

Product detail pictures:

Related Product Guide:

abide by the contract, conforms to the market requirement, joins during the market competition by its superior quality also as provides extra comprehensive and exceptional service for consumers to let them turn into significant winner. The pursue of the business, is definitely the clients' gratification for factory Outlets for Eva Laminated Glass Processing Machine - EVA Sgp TPU Glass Laminating Machine – Fangding, The product will supply to all over the world, such as: Puerto Rico, Surabaya, Zimbabwe, Taking the core concept of to be the Responsible. We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.