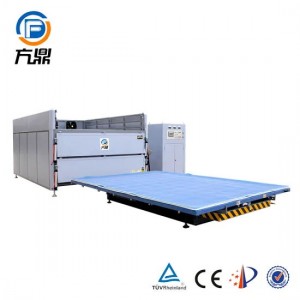

EVA glass film laminator for exterior use

Fangding Technology Co.,Ltd.

FOUR-LAYER,DOUBLE CIRCULATION

EVALAMINATED GLASS MACHINE

Newly Upgraded Safe and Reassuring

Product Introduction

| Model | Processing glass size (mm) | Rated power | Operation system | N.W. | Outside dimonsion (mm) | Floor space (mm) | Production capacity (m2/cycle) |

| FD-J-2-2 | 2000*3000*2 layers | 26kw | Siemens PLC | 2200kgs | 2600*4000*1150 | 3700*9000 | 36 |

| FD-J-2-3 | 2000*3000*3 layers | 36kw | Siemens PLC | 3500kgs | 2530*4000*2120 | 3720*9000 | 54 |

| FD-J-2-4 | 2000*3000*4 layers | 38kw | Siemens PLC | 3700kgs | 2530*4000*2150 | 3720*9000 | 72 |

| FD-J-3-2 | 2200*3200*2 layers | 28kw | Siemens PLC | 2400kgs | 2750*4200*1150 | 4000*9500 | 42 |

| FD-J-3-3 | 2200*3200*3 layers | 40kw | Siemens PLC | 3700kgs | 2730*4200*2120 | 4020*9500 | 63 |

| FD-J-3-4 | 2200*3200*4 layers | 45kw | Siemens PLC | 3900kgs | 2730*4200*2150 | 4020*9500 | 84 |

| FD-J-4-2 | 2200*3660*2layers | 30kw | Siemens PLC | 2500kgs | 2750*4600*1150 | 4000*10500 | 48 |

| FD-J-4-3 | 2200*3660*3layers | 46kw | Siemens PLC | 3800kgs | 2730*4600*2120 | 4020*10500 | 72 |

| FD-J-4-4 | 2200*3660*4layers | 52kw | Siemens PLC | 4100kgs | 2730*4600*2150 | 4020*10500 | 96 |

| FD-J-5-2 | 2440*3660*2layers | 33kw | Siemens PLC | 2600kgs | 2980*4600*1150 | 4500*10500 | 53 |

| FD-J-5-3 | 2440*3660*3layers | 52kw | Siemens PLC | 4100kgs | 2965*4600*2120 | 4520*10500 | 80 |

| FD-J-5-4 | 2440*3660*4layers | 58kw | Siemens PLC | 4300kgs | 2965*4600*2150 | 4520*10500 | 107 |

| The machine's size is customized according to your request. | |||||||

* 99% pass rate

* 50% energy saving

* High efficiency

* PLC control, Simple to operate

* High quality spare parts

* EVA/TPU/SGP film as interlayer

* Rich range of products

* Large size bending glass processing

* No waste when suddenly power off

* Free home installation and training

Model: D-J-2-2

Machine Type: Glass Laminating Machine

Max. Glass size: 2000*3000mm*2-layer

Production Capacity: 36 sqm/cycle

Place of Origin : Shandong, China

Voltage: 220/380/440V, can be customized

Power: 33KW

Dimension(L*W*H): 2600*4000*1150mm

Weight: 2200kg

Warranty: 1 Year

After-sale service: Online support, Free spare parts, Field installation, commissioning and training, Video technical support

Glass Thickness: 3-19mm

Marketing Type: New Product

Warranty of core components: 1 Year

Core Components: Motor, PLC, Pump

Product name: EVA Glass Laminating Machine

Operating temperature: 90-140℃

Control system: PLC

Heating method: Forced Convection

Operation: Automatic Control

Company

Scientific Design

Selling point description

FEATURES

The glass laminating furnace adopts the principle of high temperature vacuum extraction.

The film is placed in the middle of two or more pieces of glass. After the high temperature vacuum in the furnace, the film and glass are tightly bonded together to achieve good transparency and no bubbles. And there is no drop after breaking.

Advantage:

* Independent heating up and down, floor heating distribution, modular control, strong convection circulation of turbine

* A number of patented technologies.The heating system uses a turbine fan and a high-density explosion-proof stainless steel electric heating rod for heating. It is equipped with a temperature sensing device, a modular area heating control, intelligent self-adjusting temperature, fast heating, uniform temperature, and strong turbo fan. Convection circulation to ensure the temperature difference in the furnace within 5 degrees.

* The insulation system adopts seamless processing to minimize heat loss. Compared with similar products and equipment, it can save energy by more than 30%.

* High-performance vacuum system with automatic vacuum pressure holding, stable working around the clock, improving product efficiency and quality.

CUSTOMER CASE

The equipment is sold to Asia, Europe, Ameriaca, Southeast Asia, and has received unanimous praise from customers;

Good customer performance and the ability to mass produce orders;

Morecustomers choose to order a second unit and repeat orders for high-pressure reactors, production lines, and other products.

CUSTOMER USE CASES

The products produced by customers using equipment can be seen everywhere in daily life, such as wire clips, colored decorative glass, etc; And it has also been used in important engineering cases of world-renowned buildings and scenic spots such as glass bridges and lighthouses.

CERTIFICATE OF HONOR

R&D TECHNOLOGY TEAM

Hold a technical

review meeting

before production

Calculation based

on drawings

before production

Multiple

experienced

technical engineers

EXHIBITION STYLE

CONTACT US

Jennifer Zhu

HOT LINE +86-18906338322

Website: https://en.fangdingchina.com/

Email: sales2@foundite.com

Add: Huifeng Road, Taoluo Industrial Park, Donddang District, Rizhao City, Shandong Province, China