Chinese Professional Plyglass Autoclave - The Forced Convection Autoclave – Fangding

Chinese Professional Plyglass Autoclave - The Forced Convection Autoclave – Fangding Detail:

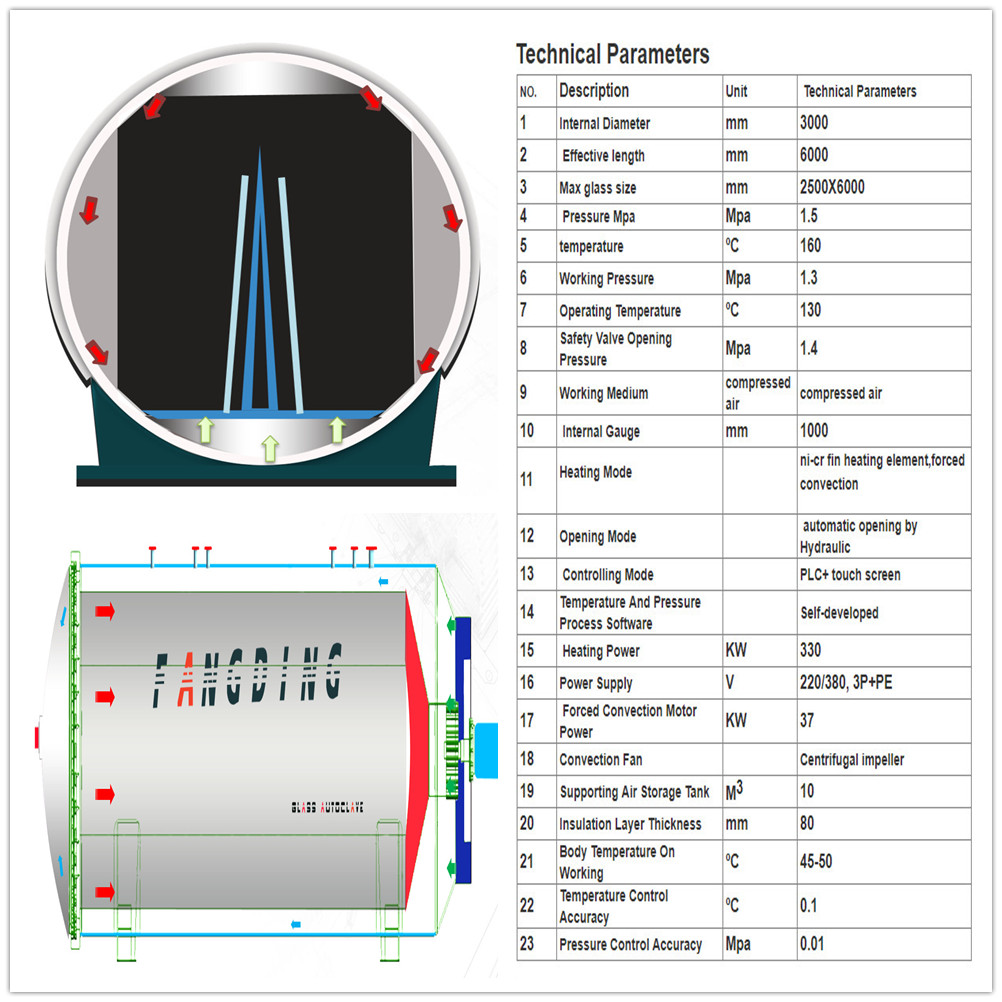

MutiFunctional Forced Convection Autoclave

1、Overall Features

It is designed and manufactured in strict accordance with the national standards,It is composed of the body , the heating system, the air circulation system, the heat preservation system, the cooling system and the safety interlock system .The gate is equipped with mechanical and electrical linkage device,it will alarm under over-temperature or over-pressure,and will cool down under over-temperature and relief pressure under over-pressure . The body equipped with the alarm and safety valve , to ensure the safety operation .The pressure control accuracy is ± 0.05KG / cm. The heating devices are evenly distributed at the inner body .It adopts unique double air circulation system to ensure the uniformity of the temperature in the autoclave and achieve the purpose of energy saving.

Forced cross convection glass autoclave is a sealed vessel with high pressure and double internal forced convection heating circulation system , in which temperature, pressure and vacuum are effectively controlled, PID control can achieve accurate control of temperature and pressure, so that temperature and pressure can change completely in accordance with the design curve

The standard working process of Fangdig glass autoclave consists of six stages: pre-temperature and pre-pressure stage, medium temperature and medium pressure stage, high temperature and high pressure stage, heat preservation and pressure protection stage, pressure preservation and cooling stage (graded cooling), and pressure relief stage.The whole operation process of temperature and pressure adopts the PID control system based on PLC. The real-time online monitoring of temperature and pressure is realized. There are fully automatic operation procedures and manual automatic switching shortcut keys.

2.Main Structure And Technical Characteristics

3.Appications:

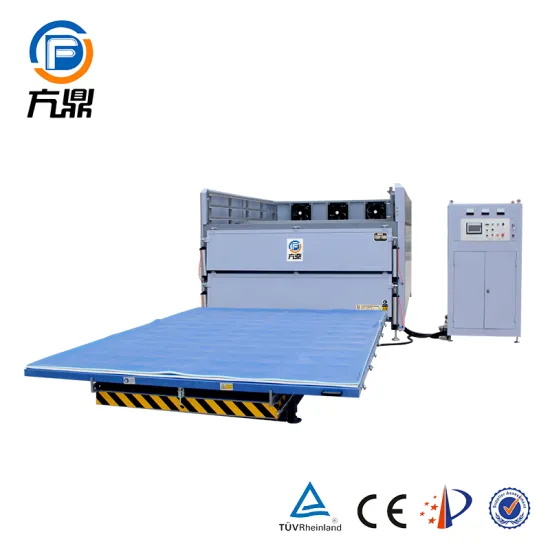

our autoclave is suitable for all kinds of glass/materials lamination .Especially for PVB or SGP interlayer film, it can ensure perfect product quality and yield;it is also widely used to process compositing materials lamination,like Carbon fiber,boron fiber ,glass fiber and metal composites ,etc,which are us

Product detail pictures:

Related Product Guide:

Every member from our high efficiency sales team values customers' needs and business communication for Chinese Professional Plyglass Autoclave - The Forced Convection Autoclave – Fangding, The product will supply to all over the world, such as: Salt Lake City, United States, Mumbai, Our company's main products are widely used all over the world; 80% of our products exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.