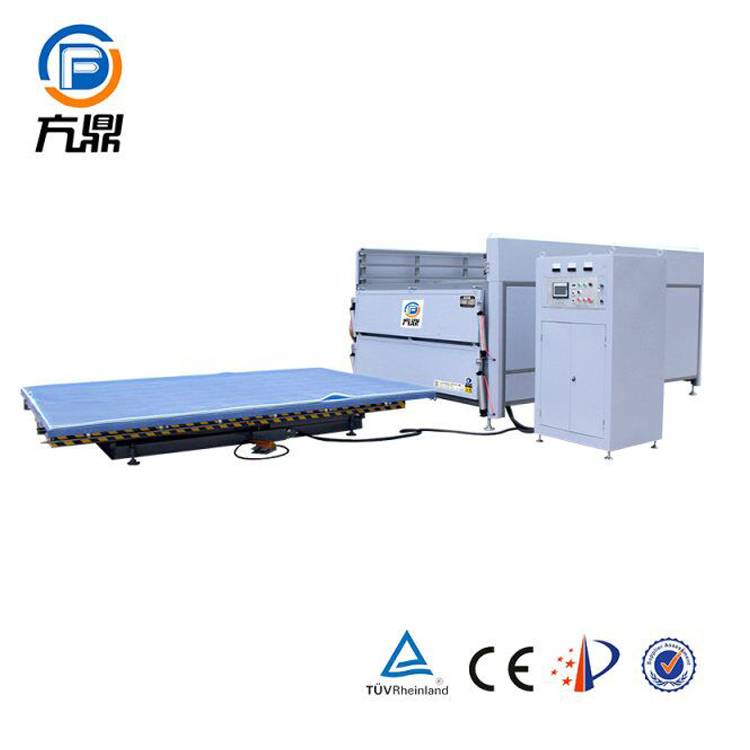

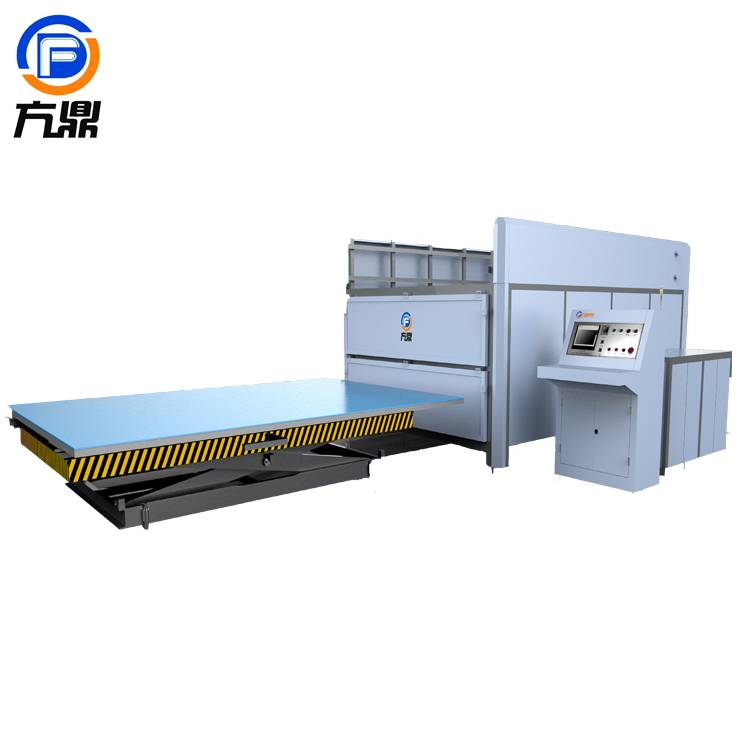

Best quality Glass Machine Production Line - Four-layers double circulation system laminated glass machine – Fangding

Best quality Glass Machine Production Line - Four-layers double circulation system laminated glass machine – Fangding Detail:

Specification:

| Model | Processing glass size (mm) | Rated power | Operation system | N.W. | Outside dimonsion (mm) | Floor space (mm) | Production capacity (m2/cycle) |

| FD-J-2-4 | 2000*3000*4 layers | 38kw | Siemens PLC | 3700kgs | 2530*4000*2150 | 3720*9000 | 72 |

| FD-J-3-4 | 2200*3200*4 layers | 45kw | Siemens PLC | 3900kgs | 2730*4200*2150 | 4020*9500 | 84 |

| FD-J-4-4 | 2200*3660*4layers | 52kw | Siemens PLC | 4100kgs | 2730*4600*2150 | 4020*10500 | 96 |

| FD-J-5-4 | 2440*3660*4layers | 58kw | Siemens PLC | 4300kgs | 2965*4600*2150 | 4520*10500 | 107 |

| Place of Origin | Shandong, China |

| Voltage | 220/380/440V, can be customized |

| Certification | CE, CSA,UL |

| Warranty | 1 Year |

| After-sale service | Online support, Free spare parts, Field installation, commissioning and training, Video technical support |

| Glass Thickness | 3-19mm |

| Core Components | Motor, heating tube, PLC, Pump |

| Product name | EVA Glass Laminating Machine |

| Operating temperature | 90-140℃ |

| Control system | PLC |

| PLC | Siemens Brand |

| Heating method | Forced Convection |

| Operation | Automatic Control |

| Processable glass type | Normal Glass |

4-Layer glass lamination machine with double system

4 layers machine is equipped with double independent heating system.

Mainly working system includes cooling, heating, vacuum, PLC, glass lifting table.

Double independent system: laminating two different kinds of glass at the same time.

* Independent heating up and down, floor heating distribution, modular control, strong convection circulation of turbine fans.

* A number of patented technologies. The heating system uses a turbine fan and a high-density explosion-proof stainless steel electric heating rod for heating. It is equipped with a temperature sensing device, a modular area heating control, intelligent self-adjusting temperature, fast heating, temperature balance, and strong turbo fan.

* Convection circulation to ensure no temperature difference in the furnace.

* The insulation system adopts seamless processing to minimize heat loss. Compared with similar products and equipment, it can save energy by more than 30%.

* High-performance vacuum system with automatic vacuum pressure holding, stable working around the clock, improving product efficiency and quality.

* Elevator lifting system, efficient and stable operation, mature technology.

Features:

* 99% pass rate

* 50% energy saving

* High efficiency

* PLC control, Simple to operate

* High quality spare parts

* EVA/TPU/SGP film as interlayer

* Rich range of products

* Large size bending glass processing

* No waste when suddenly power off

* Free home installation and training

Company

Fangding Technology Co., Ltd is a high-tech enterprise which was founded in October 2003, located in Taoluo industrial park, Donggang district, Rizhao city, covering an area of more than 20,000 square meters, with a registered capital of 100 million yuan, specializing in R&D, production and sales & service of the laminated glass machinery and the interlayer films, the main products are EVA laminated glass machine, Heat Soak Furnace, Smart PVB glass laminating line and EVA, TPU and SGP films.

The company has a large number of skilled senior technical personnel and experienced management personnel, established cooperation with many scientific research institutions, has been committing to provide full set of solutions of the glass laminating for the deep-processing enterprises; the company has reached co-operations with many global top 500 companies.

In the international market, the products has been exported to Asia, Europe, America and other more than 68 countries and regions. Be responsible for the customers and develop together with them! It has laid a solid foundation for enterprises to compete on the international stage. Our company has won the trust and praise from the customers all over the world for years.

Looking at the world and advancing with the times, we focus on the details and refine the quality. We gather bits and pieces to chase the future. Fangding Technology uses the passion of innovation to ignite the development of high-end technology enterprises of China.

Exhibition

The company participated in the world glass industry well-known exhibitions every year, such as Germany Dusseldorf international glass industry exhibition, China international glass industry exhibition, China international window and curtain wall exhibition, Italy Milan international glass industry exhibition, the Middle East (Dubai) international glass exhibition, the United States Atlanta international window and curtain wall exhibition and other exhibitions.

During the exhibition, through the on-site processing of the laminated glass, Fangding presented its unique design style and manufacturing process to the customers!

Packing & Delivery

Wrapped with moisture proof film

Plywood suitable for container loading

Application

Outdoor architecture glass and indoor decorative glass, including glass wall, ordinary float laminated glass, curved laminated glass, tempered laminated glass, high-level office building, furniture, church, villa, wall windowpane, tabletop, craft glass, colored laminated glass, LED glass, smart glass, bullet-proof glass, multi-layer laminated glass, laminated silk glass, household appliances panel glass, glass corner, background wall and video wall glass, coffee table surface glass, partition screen, frameless painting laminated glass and personalized portrait glass etc.

Product detail pictures:

Related Product Guide:

It truly is a great way to improve our merchandise and repair. Our mission should be to create imaginative products to prospects with a excellent knowledge for Best quality Glass Machine Production Line - Four-layers double circulation system laminated glass machine – Fangding, The product will supply to all over the world, such as: Singapore, Afghanistan, Kuala Lumpur, If you need any of our products, or have other items to be produced, please send us your inquiries, samples or detailed drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!