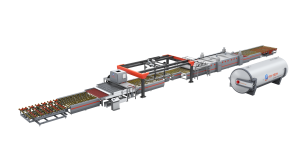

Automatic glass lamination production line with autoclave

FANGDING TECHNOLOGY CO., LTD

LAMINATED GLASS

PRODUCTION LINE

AUTOCLAVE

THE PREFERRED EQUIPMENT FOR

GLASS LAMINATING LINE

--TO PROVIDE YOU WITH HIGH-QUALITY PRODUCTS --

Quailty

Assurance

High quality

hardware

Exquisite

craftsmanship

Perfect after-sales

service

PRODUCT DETAILS

-- RELIABLE QUALITY AND ASSURED PURCHASE. --

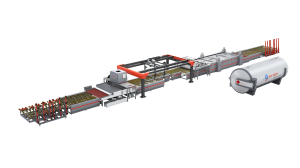

FULL AUTOMATIC LAMINATED GLASS PRODUCTION LINE

We provide a full range of laminated glass equipment solutions. Specifications and configurations are optional, tell us your specific requirements, and we will tailor the optimal solution for you.

| Production | Automatic laminated glass production line |

| Machine model | FD-A2500 |

| Rated power | 540KW |

| Processing glass size | Max. glass size: 2500X6000mm Min.glass size: 400mmx450mm |

| Glass thickness | 4~60mm |

| Floor space | L*W: 60000mm×8000mm |

| Voltage | 220-440V 50-60Hz 3-phase AC |

| Working period | 3-5h |

| Working temperature | 60-135ºC |

| Net Weight | 50t |

| Operation system | Siemens PLC centralized control |

| Productivity | 300-500 Sq.m/cycle |

Process Flow

loading glass sheet→ washing and drying→ assembling → transition → preheat and prepress → unloading the combined glass sheet → into autoclave → finished product

INTELLIGENT LAMINATED GLASS PRODUCTION LINE

PRODUCT FORM

1. Glass washing & drying machine

2. Glass positioning conveyor or Glass taking conveyor(Alternative)

3. Double station glass combining machine

4. Semi-automatic suction cup hanger

5. The horizontal 3-roller film storage machine

6. Transition conveyor

7. Roller pressing machine

8. Glass autoclave

PRODUCTS ADVANTAGES

We have a professional R&D department, and our engineers have many years of practical and technical experience. From the glass loading machine, the laminating system, the pre-press machine to the autoclave, we are constantly improving and innovating, striving for excellence, and are committed to providing the market with better products.

TECHNICAL FEATURES

1. All sections of the line adopt PLC centralized control system, frequency control and three HMI interface operations.

2. The special purpose segment is equipped with encoder and servo motor to ensure equipment stability and machining accuracy.

3. High efficiency, energy saving, environmental protection, noise and other special controls shall be considered in the whole line design.

4. The film spreader system adopts automatic film placing and electric film returning. 3 rolls of plastic film lay, easy to operate, quick and easy film change.

5. The structure of the initial press is reasonable, easy to operate.The whole machine runs smoothly and reliably, and is centrally controlled by the assembling room.The heating area is evenly distributed, and domestic medium-wave infrared heating tube is adopted for heating.

6. Adopt mechanical turnover unloading table to unload.

7. The glass autoclave is automatically controlled by PLC and operated by HMI interface to achieve safety, reliability, high efficiency and energy saving.

COMPANY PROFILE

AFTER-SALES

SERVICE CAPABILITY

SINCERE

QUALITY

STRONG

PRICE

R & D TECHNICAL TEAM

01 Technical seminar

02 Drawing calculation

03 Detail communication

04 Experienced

QUALIFICATION

CERTIFICATE

EXHIBITION STYLE

CUSTOMER REVIEW

The equipment is sold to varous countries and has received unanimous praise from customers.

CONTACT US

Jennifer Zhu

HOT LINE +86-18906338322

Website: https://en.fangdingchina.com/

Email: sales2@foundite.com

Add: Huifeng Road, Taoluo Industrial Park, Donddang District, Rizhao City, Shandong Province, China

![[Copy] OEM/ODM Supplier Clear TPU Ppf Wholesale Factory Price Anti-Scratch Self Healing TPU Film OEM Customized](https://cdn.globalso.com/fangdingmachinery/未标题-1-300x300.jpg)