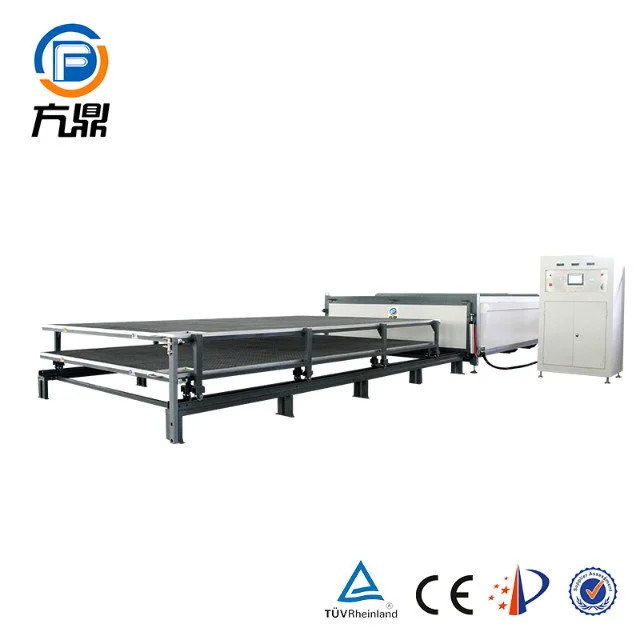

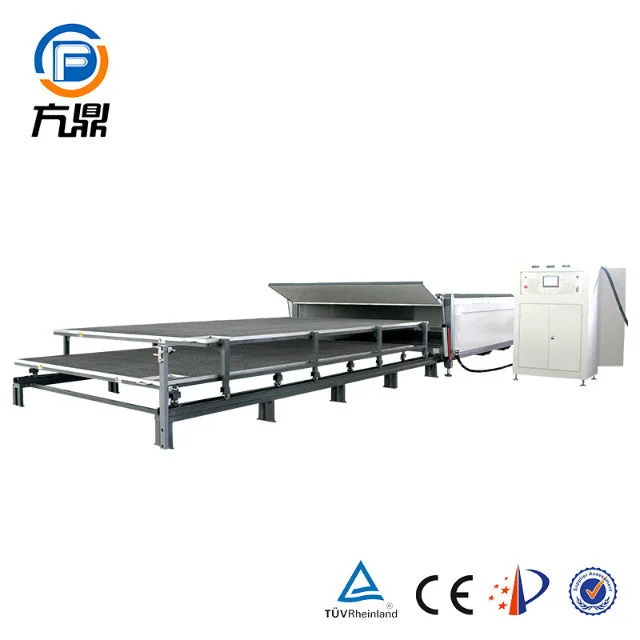

2020 New Style Eva Glass Combined Machine Furnace - Fangding Machine Process Laminated Glass with EVA/Sgp/TPU Film – Fangding

2020 New Style Eva Glass Combined Machine Furnace - Fangding Machine Process Laminated Glass with EVA/Sgp/TPU Film – Fangding Detail:

Basic Info.

| Model NO.! | FD-J–2-2 |

| Origin | China |

FANGDING Lamination Machines

Since 2003, Fangding begin producing glass laminating machine, keep improving and inovation, we use unique design of heating and vacuum systems, the heating is evenly in the heat box, temperature difference is less than 3 degrees. The glass laminating machine has two heating rooms, each room has independent control systems.Make the producing very smart , heating more quickly, saved around 30% engergy comparing to other Chinese machines.

EVA laminating glass machine can produce laminated glass withou the use of and autoclave. The machine can work with silk, paper, plastic film, metal mesh, fiber mesh, switchable film and many other decorative film.

Heating Elements:

The heating elements are placed in the furnace evenly and resonable. The heating is provided with electric radiant heat and is evenly distrubuted with the assisstance of 2 convection fans for very precise heating. This setup will quickly reach the target temperature, the temperature difference is bellow 3 degrees, the heating is evenly , the laminate glass quality is excellent.

PRODUCT NAME: Fangding EVA glass laminating machine

ITEM#: FD-J-2-2

MAIN TECHNICAL PARAMETERS:

POWER INPUT: 220-480V THREEPHASE ALTERBATING CURRENT

POWER CONSUMPTION:38KW / H

MAX PROCESSING GLASS SIZE: Max size (mm): 2000 mm*3000mm

Max Arch height (mm): 400 mm(can design as your requirement even higher)

Max Thickness (mm): 36 mm

EFFICIENCY: Forming cycle (minute/furnace): 75-90min

Max processing area (M2 /furnace): 36M2

OPERATION SYSTEM: PLC, Man machine conversation.

OPERATION PLATEFORM: 2 layers

WORKING TEMPERATURE: 90-140 0C

MACHINERY OUTSIDE DIMENTION :2600mm*4000mm*1150mm

N.W: 2200kgs

Machine main configeration

1). Siemens PLC control

2).one heating rooms

3)two plates/layers

4). one set vacuum systems

5) one set PLC system

5). One ground rail

6). two sets vacuum bed

7). Teflon Mesh:2 sets

Special desgin avaliable

We are leading manufacture in China with more than 17 years experience in glas laminated manufacture machine field.We have research team with 8 employees, if you have any special requirement ,contact with us freely.And warmly welcome you to visit us!

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for 2020 New Style Eva Glass Combined Machine Furnace - Fangding Machine Process Laminated Glass with EVA/Sgp/TPU Film – Fangding, The product will supply to all over the world, such as: Mexico, Miami, Rome, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!